Implementing 5S training, a core lean management strategy, revolutionizes workplace organization and drives significant improvements in efficiency. This Japanese-rooted methodology, comprising sorting, setting in order, shining (cleaning), standardizing, and sustaining, transforms chaotic spaces into streamlined, productive environments. By fostering a culture of continuous enhancement, 5S continuous improvement ensures consistent, standardized processes, empowering employees to focus on value-added tasks while eliminating waste. Integrating this approach leads to faster workflows, improved quality, enhanced collaboration, increased employee engagement, and ultimately, long-term organizational success in today's dynamic business landscape.

“Unleash the power of continuous improvement with our comprehensive guide. We explore essential practices like Lean Management and the foundational role of 5S Training in enhancing workplace efficiency. Discover how process standardization, when integrated with 5S principles, drives long-term success.

From understanding the core concepts to best practices for sustained enhancement, this article covers everything. Master techniques to organize and standardize your workspace effectively, leading to a culture of ongoing improvement.”

- Understanding Continuous Improvement: The Foundation of Lean Management

- The Role of 5S Training in Workplace Organization and Standardization

- Implementing Process Standardization for Long-Term Success

- Key Benefits of Integrating 5S Principles into Continuous Improvement Efforts

- Best Practices for Sustaining a Culture of Ongoing Enhancement

Understanding Continuous Improvement: The Foundation of Lean Management

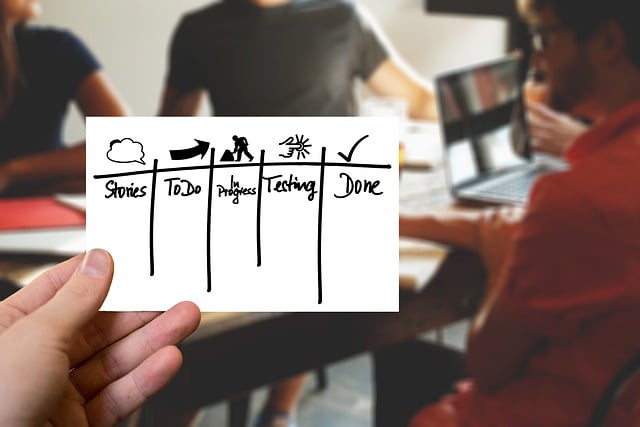

Continuous Improvement, at its core, is a philosophy that drives organizations to consistently optimize their processes and eliminate waste. This concept forms the backbone of Lean Management, a system designed to enhance efficiency and productivity through streamlined workflows and workplace organization. The foundation of this approach lies in the 5S training methodology—Sort, Set in Order, Shine, Standardize, and Sustain—which serves as a powerful tool for achieving process standardization.

By implementing 5S continuous improvement, organizations can transform their workplaces into highly organized and efficient environments. Each ‘S’ represents a crucial step in this journey: sorting through unnecessary items to identify only essential tools and resources; setting them in order to create a logical workflow; shining a light on potential issues or inefficiencies by visually inspecting every corner of the workplace; standardizing processes to ensure consistency, and finally, sustaining these improvements through ongoing maintenance and continuous learning.

The Role of 5S Training in Workplace Organization and Standardization

The implementation of 5S training is a powerful strategy within lean management aimed at transforming workplaces and fostering a culture of continuous improvement. This structured approach, rooted in Japanese organizational principles, emphasizes the importance of workplace organization and process standardization. By teaching employees the fundamentals of sorting, setting in order, shining (cleaning), standardizing, and sustaining, 5S training equips them with the skills to create an efficient and safe work environment.

In practice, this involves organizing tools and equipment, eliminating waste, establishing clear standards for tasks, and promoting a mindset committed to consistent improvement. The result is a more streamlined workflow, reduced errors, and enhanced productivity. This method not only benefits individual workers but also the organization as a whole, ensuring that processes are optimized and resources are utilized effectively, thereby driving overall success in an ever-evolving business landscape.

Implementing Process Standardization for Long-Term Success

Implementing process standardization is a key aspect of achieving long-term success in any organization. By adopting lean management principles and integrating 5S training into daily operations, businesses can create a culture of continuous improvement and workplace organization. The 5S methodology—Sort, Set in Order, Shine, Standardize, and Sustain—serves as a powerful framework for streamlining workflows and eliminating waste. This approach fosters an environment where every employee understands their role in maintaining efficiency and quality standards.

Through regular 5S training sessions, staff members learn to identify and eliminate non-value-added activities, organize tools and equipment for easy accessibility, maintain cleanliness and order at their workstations, establish standardized procedures, and continuously strive for improvement. This holistic approach not only enhances productivity but also boosts employee engagement and job satisfaction. By embracing process standardization, organizations can ensure sustained growth, enhanced customer satisfaction, and a competitive edge in the market.

Key Benefits of Integrating 5S Principles into Continuous Improvement Efforts

Integrating 5S principles into continuous improvement efforts offers significant advantages for organizations aiming to enhance efficiency and productivity. 5S training, rooted in lean management, provides a structured framework for workplace organization. By focusing on sorting, setting in order, shining (cleaning), standardizing, and sustaining, teams can create a highly organized and visually managed environment. This promotes faster workflows, reduces waste, and improves quality through process standardization.

5S continuous improvement empowers employees to take ownership of their workspace and processes. Visual management tools and standardized procedures ensure everyone understands their role in maintaining an efficient system. This fosters collaboration and continuous learning as team members learn from each other’s practices. Ultimately, these principles lead to increased employee engagement, improved safety, and better overall performance.

Best Practices for Sustaining a Culture of Ongoing Enhancement

To sustain a culture of ongoing enhancement, organizations should integrate best practices that promote continuous improvement into their daily operations. One effective approach is to implement 5S training, a lean management technique focusing on workplace organization. This involves sorting, setting in order, shining (cleaning), standardizing, and sustaining—transforming workspaces into visually organized environments that enhance productivity and efficiency. By teaching employees these principles, companies create an atmosphere where improvement is normalized rather than exceptional.

Additionally, process standardization plays a pivotal role in maintaining this culture. Standardized processes ensure consistency across operations, enabling teams to identify and eliminate non-value-added steps. This not only streamlines workflows but also empowers employees to focus on tasks that drive business value. Regular reviews and updates of these standards keep the organization agile, allowing it to adapt swiftly to changing market demands and customer needs.

The journey towards exceptional performance and efficiency in any organization is an ongoing process, and continuous improvement is its heartbeat. By integrating 5S training and embracing lean management principles, businesses can transform their operations. This article has explored the power of 5S as a foundational tool for workplace organization and standardization, demonstrating its significant role in long-term success. The key benefits are clear: improved productivity, enhanced quality, and a culture of ongoing enhancement. By adopting best practices that sustain this culture, organizations can ensure continuous growth and stay ahead in an ever-evolving market. Process standardization is the linchpin, enabling efficient workflows and fostering a dedicated workforce.