5S training, rooted in Japanese lean management principles, is a powerful tool for transforming workplace organization and efficiency. This methodology, consisting of sorting, setting in order, cleaning (shining), standardizing, and sustaining, promotes process standardization and continuous improvement. By empowering employees to maintain organized workstations, 5S fosters accountability, reduces waste, and enhances overall productivity. Combining 5S with lean management principles significantly boosts efficiency, quality, and employee engagement, leading to a culture of continuous enhancement and competitive advantage in today's dynamic market.

“Unleash productivity and transform your workplace with systematic workflow improvement. This comprehensive guide explores powerful strategies, from foundational 5S training for optimal organization to advanced lean management techniques for process optimization. Discover how implementing 5S continuous improvement strategies enhances efficiency and drives long-term success through process standardization. Learn key performance indicators and cultivate a culture of continuous enhancement, empowering employees to actively participate in revolutionizing workflows.”

- Understanding the Foundation: 5S Training and Its Role in Workplace Organization

- The Principles of Lean Management: Optimizing Processes for Continuous Improvement

- Unlocking Efficiency: Implementing 5S Continuous Improvement Strategies

- Standardization Techniques: Streamlining Workflows for Long-Term Success

- Measuring Success: Key Performance Indicators for Workflow Improvement

- Cultivating a Culture of Continuous Enhancement: Engaging Employees in the Process

Understanding the Foundation: 5S Training and Its Role in Workplace Organization

In the realm of systematic workflow improvement, 5S training stands out as a cornerstone for enhancing workplace organization and efficiency. This lean management philosophy, deeply rooted in Japanese manufacturing principles, focuses on sorting, setting in order, shining (cleaning), standardizing, and sustaining—a framework known as the 5S methodology. By implementing this approach, organizations can achieve remarkable transformations in their work environments, making processes more streamlined and optimized.

5S training is not just about organizing physical spaces; it’s a catalyst for process standardization and continuous improvement. It empowers employees to take ownership of their workstations, fostering a culture where orderliness and efficiency are everyone’s responsibility. This disciplined approach ensures that each step in the workflow is standardized, reduced waste, and improved productivity become inherent parts of the organizational DNA.

The Principles of Lean Management: Optimizing Processes for Continuous Improvement

The Principles of Lean Management focus on optimizing processes to achieve continuous improvement, eliminating waste, and enhancing overall workplace efficiency. At the core of this philosophy lies the renowned 5S training methodology, which promotes disciplined workplace organization. By adhering to the 5S principles—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—organizations can systematically streamline their operations. This involves categorizing items, arranging them logically, maintaining a clean and safe environment, establishing standardized procedures, and ensuring these practices are consistently followed.

Lean management encourages a culture of continuous learning and enhancement. Process standardization ensures that tasks are executed in the most efficient way possible, minimizing errors and maximizing productivity. By implementing 5S continuous improvement initiatives, businesses can identify bottlenecks, reduce unnecessary steps, and foster an environment where every employee contributes to optimizing workflows. This holistic approach not only improves operational efficiency but also enhances job satisfaction and overall organizational performance.

Unlocking Efficiency: Implementing 5S Continuous Improvement Strategies

Unlocking efficiency and enhancing productivity is achievable through the implementation of 5S continuous improvement strategies. 5S training, rooted in lean management principles, offers a structured approach to workplace organization. This methodology includes sorting, setting in order, shining (cleaning), standardizing, and sustaining – five key steps that transform cluttered workspaces into streamlined operations. By focusing on process standardization and eliminating waste, organizations can significantly boost their efficiency.

5S continuous improvement is not just about physical space; it also encompasses the normalization of efficient processes. This involves identifying and documenting workflows, removing unnecessary steps, and ensuring every employee understands and adheres to standardized procedures. When incorporated into daily operations, 5S principles create a culture of excellence, fostering an environment where inefficiencies are quickly identified and addressed, ultimately driving organizational success.

Standardization Techniques: Streamlining Workflows for Long-Term Success

Standardization techniques play a pivotal role in achieving long-term success through systematic workflow improvement. Among various methodologies, 5S training stands out as a powerful tool for workplace organization. This Japanese approach emphasizes sorting, setting in order, shining (cleaning), standardizing, and sustaining to create an efficient, safe, and visually appealing work environment. By implementing 5S continuous improvement practices, organizations can significantly enhance productivity and quality while reducing waste and errors.

Lean management principles complement 5S by focusing on eliminating non-value-added activities. Process standardization ensures that tasks are performed consistently, allowing for better forecasting, reduced lead times, and improved customer satisfaction. This synergy between 5S training and lean management fosters a culture of continuous improvement, where every step in the workflow is scrutinized for potential enhancements. Such practices not only drive operational excellence but also create a more engaged workforce, as employees actively participate in streamlining their own work processes.

Measuring Success: Key Performance Indicators for Workflow Improvement

Measuring success is a critical aspect of systematic workflow improvement initiatives, be it through 5S training or lean management principles. Key Performance Indicators (KPIs) play a pivotal role in gauging the effectiveness of process changes and identifying areas that require further optimization. These KPIs should align with the goals of workplace organization and continuous improvement, such as enhancing efficiency, reducing waste, and improving quality.

For instance, metrics like cycle time reduction, defect rates, and employee productivity gains can serve as relevant KPIs. Process standardization techniques, including 5S methodologies, aim to create an organized, efficient, and sustainable work environment. By regularly monitoring these KPIs, organizations can ensure that their workflow improvements are not just temporary fixes but lasting solutions that drive business value and competitive advantage in a dynamic market.

Cultivating a Culture of Continuous Enhancement: Engaging Employees in the Process

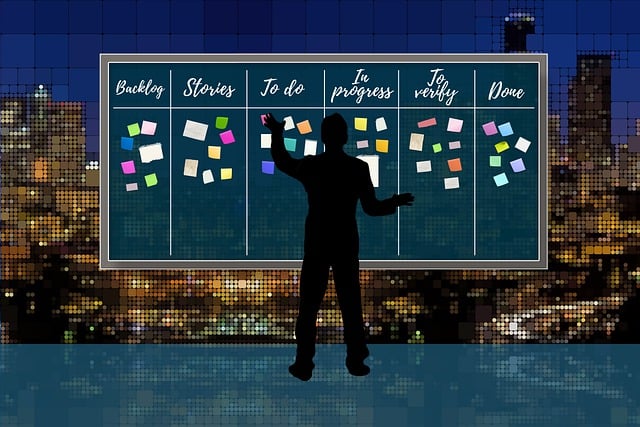

In today’s competitive business landscape, cultivating a culture of continuous enhancement is paramount to staying ahead. This involves empowering employees at all levels to identify inefficiencies and propose solutions, fostering an environment where every voice is heard and valued. By integrating principles from lean management and 5S training, organizations can achieve remarkable results in workplace organization and process standardization. These methodologies encourage a systematic approach to eliminating waste and streamlining operations, ultimately enhancing productivity and employee engagement.

Engaging employees in the continuous improvement process not only drives innovation but also creates a sense of ownership and pride within the team. 5S continuous improvement, for instance, focuses on sorting, setting in order, shining (cleaning), standardizing, and sustaining, providing a structured framework for employees to participate actively in workplace optimization. This collaborative effort ensures that improvements are sustainable, as employees become invested in maintaining the new standards, leading to long-term benefits for both the organization and its people.

Systematic workflow improvement is not just about optimizing processes; it’s about cultivating a culture of continuous enhancement. By combining essential practices like 5S training and lean management principles, organizations can unlock efficiency, streamline workflows, and drive long-term success. Implementing 5S continuous improvement strategies ensures that every step in the process is standardized and optimized, while measuring success with key performance indicators provides a clear roadmap for future enhancements. Engaging employees in this transformative journey is crucial, fostering an environment where everyone contributes to workplace organization and embraces their role in revolutionizing operational efficiency.