In today's competitive business environment, success hinges on implementing efficient workplace organization strategies like 5S training and Lean Management. The 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) transforms chaotic spaces into streamlined operations through process standardization, waste elimination, and improved employee engagement. Lean management, focusing on process optimization and removing non-value-added activities, enhances productivity, quality, and resource efficiency. Integrating these approaches cultivates a culture of continuous improvement, empowering employees to optimize workflows and drive overall organizational success.

In today’s fast-paced business landscape, an efficiency-driven workplace culture is a competitive advantage. This article explores how 5S training and Lean Management principles can transform organizations, fostering a culture of excellence through workplace organization and process standardization. By implementing 5S continuous improvement strategies, companies can enhance productivity, reduce waste, and cultivate an environment where every employee contributes to overall success. Discover best practices for creating a high-performance work space that drives results.

- Understanding Efficiency-Driven Workplace Culture: A Foundation for Success

- The Role of 5S Training and Lean Management in Enhancing Organization

- Implementing Continuous Improvement with 5S: Strategies for Standardization

- Benefits and Best Practices for Cultivating an Efficient Work Environment

Understanding Efficiency-Driven Workplace Culture: A Foundation for Success

In today’s fast-paced business environment, an efficiency-driven workplace culture is more crucial than ever for achieving success and staying competitive. At its core, this culture prioritizes maximizing productivity by minimizing waste through structured processes and a disciplined approach to workplace organization. The concept draws heavily from methodologies like Lean management and 5S training, which focus on process standardization and continuous improvement.

By implementing 5S principles—sort, set in order, shine (clean), standardize, sustain—organizations can create an environment that promotes efficiency at every level. This involves not only physical organization but also mental and operational clarity. Lean management practices further enhance this by identifying and eliminating non-value-added activities, streamlining workflows, and fostering a mindset of continuous improvement among employees. Such strategies ensure that everyone in the workplace is aligned towards optimizing productivity and quality while reducing time and resource waste, ultimately contributing to overall success and growth.

The Role of 5S Training and Lean Management in Enhancing Organization

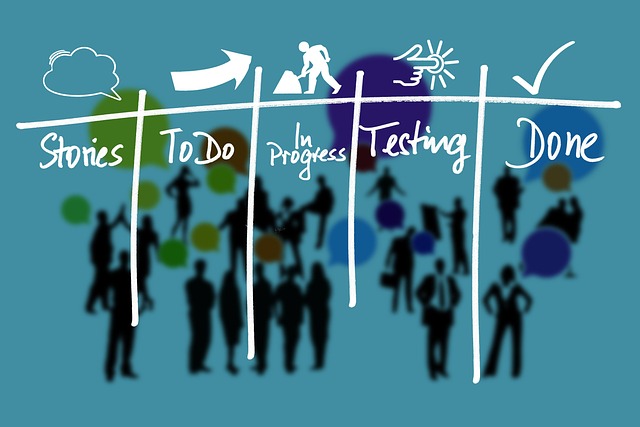

In today’s fast-paced business landscape, efficient workplace organization is key to staying competitive. 5S training and Lean Management principles emerge as powerful tools for achieving this. 5S, an acronym for Sort, Set in Order, Shine (Clean), Standardize, and Sustain, is a continuous improvement methodology that focuses on creating a visually organized and streamlined work environment. By implementing 5S, organizations can enhance productivity by eliminating waste, simplifying processes, and promoting a culture of order and discipline.

Lean Management, rooted in manufacturing but now applied across various sectors, complements 5S by emphasizing the importance of process standardization and elimination of non-value-added activities. This approach ensures that tasks are executed efficiently, minimizing delays and maximizing resource utilization. Integrating 5S training with Lean Management principles fosters a workplace culture centered on continuous improvement, where every employee plays a role in optimizing workflows and enhancing overall organizational efficiency.

Implementing Continuous Improvement with 5S: Strategies for Standardization

Implementing Continuous Improvement with 5S is a powerful strategy for cultivating a high-performance workplace culture driven by efficiency. 5S, short for Sort, Set in Order, Shine, Standardize, and Sustain, is a proven lean management methodology that transforms disorganized spaces into streamlined operations. By focusing on process standardization through 5S training, organizations can enhance productivity, reduce waste, and create an environment conducive to ongoing optimization.

This method encourages employees to actively participate in identifying inefficiencies within their workflow and implementing solutions for improvement. Regular 5S audits ensure that standardized procedures remain in place, fostering a culture of continuous learning and adaptation. Leveraging 5S training empowers teams to take ownership of their work environments, leading to increased accountability and a more organized, efficient workplace.

Benefits and Best Practices for Cultivating an Efficient Work Environment

Cultivating an efficient work environment brings numerous benefits, from increased productivity to enhanced employee morale and job satisfaction. Implementing best practices inspired by lean management principles, such as 5S training, can dramatically transform a workplace. The 5S methodology—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—is a powerful tool for promoting workplace organization and continuous improvement. By teaching employees to systematically organize their workspace, maintain cleanliness, and standardize processes, companies can eliminate waste and streamline operations.

Additionally, fostering a culture of continuous improvement encourages employees at all levels to identify inefficiencies and propose solutions. Process standardization ensures that tasks are completed consistently and effectively, reducing errors and saving time. Effective workplace organization not only creates a more pleasant physical environment but also fosters a mental space conducive to focus and creativity. Managers play a vital role in championing these practices, leading by example and empowering their teams to embrace efficiency as a core value.