In today's competitive business environment, effective workplace organization and process standardization are crucial for quality improvement. 5S training, a powerful lean management strategy, teaches employees to identify waste, streamline processes, and establish consistent standards. By sorting, setting in order, cleaning, standardizing, and sustaining (the 5S principles), organizations can achieve higher efficiency, reduce errors, and improve product/service quality. This method fosters a culture of continuous enhancement, boosting productivity and employee morale while ensuring optimal workflow efficiency through structured organization and standardization.

In today’s competitive landscape, successful businesses are defined by their relentless pursuit of quality excellence. This article explores a comprehensive quality improvement strategy, delving into foundational practices like 5S training and its pivotal role in enhancing operational efficiency. We also uncover the transformative power of integrating Lean management principles, unlocking productivity through meticulous workplace organization, and highlighting sustainable success strategies through continuous improvement and process standardization techniques.

- Understanding the Foundation: 5S Training and Its Role in Quality Improvement

- Integrating Lean Management Principles for Efficient Processes

- Unlocking Productivity through Comprehensive Workplace Organization

- Sustaining Success: Continuous Improvement and Process Standardization Techniques

Understanding the Foundation: 5S Training and Its Role in Quality Improvement

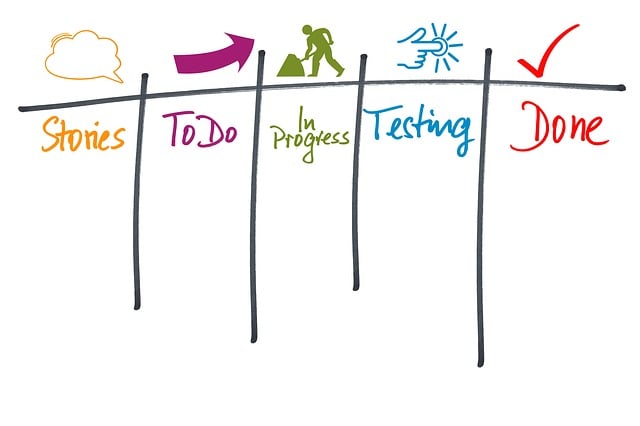

In today’s competitive business landscape, effective workplace organization and process standardization are key drivers for quality improvement initiatives. Among various tools at their disposal, 5S training stands out as a powerful lean management strategy that fosters a culture of continuous improvement. The term ‘5S’ refers to five Japanese words—Seiri (sort), Seiton (set in order), Seiso (shine), Seiketsi (standardize), and Shitsuke (sustain)—which collectively guide employees in maintaining an organized, clean, and efficient workspace.

By participating in 5S training, staff members learn to identify waste, streamline processes, and establish consistent standards across the organization. This holistic approach not only enhances productivity but also significantly reduces errors, leading to improved product or service quality. In essence, 5S training serves as a foundational step in any quality improvement strategy by empowering employees with the knowledge and skills required to create an environment conducive to continuous enhancement.

Integrating Lean Management Principles for Efficient Processes

Integrating Lean Management Principles is a powerful strategy for enhancing process efficiency and driving quality improvement. At its core, lean management focuses on eliminating waste and maximizing value in various business processes. One effective method to achieve this is through 5S training, a structured approach that involves sorting, setting in order, shining (cleaning), standardizing, and sustaining. This system transforms the workplace organization by encouraging employees to be active participants in process improvement.

By implementing 5S continuous improvement, organizations can achieve higher levels of process standardization and overall efficiency. It promotes a culture where every step is examined critically, ensuring that only value-added activities remain. This method not only improves productivity but also reduces errors and waste, leading to a smoother workflow and enhanced product or service quality.

Unlocking Productivity through Comprehensive Workplace Organization

In today’s competitive business landscape, unlocking productivity through comprehensive workplace organization is no longer an option but a necessity. Implementing 5S training, a core principle of lean management, serves as a powerful catalyst for enhancing efficiency and reducing waste. By fostering a culture of order and structure, organizations can streamline processes, eliminating unnecessary steps and streamlining workflow. This results in faster turnaround times, improved quality, and enhanced employee morale.

Workplace organization extends beyond physical space. It encompasses every aspect of the work environment, from equipment placement to document management systems. Standardizing processes through 5S continuous improvement methodologies ensures that everyone follows consistent procedures, minimizing errors and maximizing productivity. When employees understand their roles and responsibilities within this structured framework, they can focus on delivering exceptional results, driving overall business success.

Sustaining Success: Continuous Improvement and Process Standardization Techniques

Maintaining success in quality improvement initiatives requires a commitment to continuous learning and optimization. Implementing 5S training is a powerful method to achieve this, focusing on sorting, setting in order, shining (cleaning), standardizing, and sustaining. This approach transforms the workplace into an organized and efficient environment, laying the foundation for consistent high-quality output. By teaching employees these principles, organizations can foster a culture of continuous improvement.

Integrating lean management practices further enhances process standardization techniques. Lean management emphasizes the elimination of waste and streamlining workflows, ensuring every step adds value to the end product or service. Standardization through 5S and lean methodologies results in improved productivity, reduced errors, and enhanced customer satisfaction. These strategies work hand-in-hand to create a robust quality improvement strategy that drives organizational success over time.