5S training, a lean management approach, revolutionizes workplace organization and continuous improvement through sorting, setting in order, cleanliness, standardizing processes, and sustaining these practices. This method minimizes waste, enhances productivity, and promotes quality control by teaching employees to categorize, clean, and standardize their workspace, ultimately driving operational excellence and adaptability in today's competitive business landscape.

In today’s competitive landscape, systematic workflow improvement is no longer an option but a necessity. This comprehensive guide delves into the transformative power of 5S training and lean management principles for enhancing operational efficiency. From understanding the foundational 5S basics to implementing process standardization and unlocking the potential of continuous improvement, this article provides actionable insights on how to streamline your workplace organization for sustained success.

- Understanding the Foundation: 5S Training Basics

- Implementing Lean Management Principles

- Workplace Organization: Streamlining Spaces

- Unlocking Efficiency: Process Standardization

- Continuous Improvement: The 5S Journey Ahead

Understanding the Foundation: 5S Training Basics

Understanding the Foundation: 5S Training Basics

In today’s competitive business landscape, efficient and streamlined workflows are essential for success. One proven methodology that forms the backbone of workplace organization and continuous improvement is 5S training, rooted in lean management principles. By focusing on sorting, setting in order, shining (cleanliness), standardizing processes, and sustaining these practices, organizations can achieve remarkable efficiency gains.

5S training involves a systematic approach to organizing the workplace, eliminating waste, and improving overall productivity. This method begins with identifying and categorizing items within the work area, discarding unnecessary elements, and arranging tools and materials in a logical manner. Shining emphasizes maintaining a clean and safe environment, which not only enhances aesthetics but also promotes better focus and efficiency among employees. Standardization ensures that processes are consistently followed, facilitating process standardization and reducing errors.

Implementing Lean Management Principles

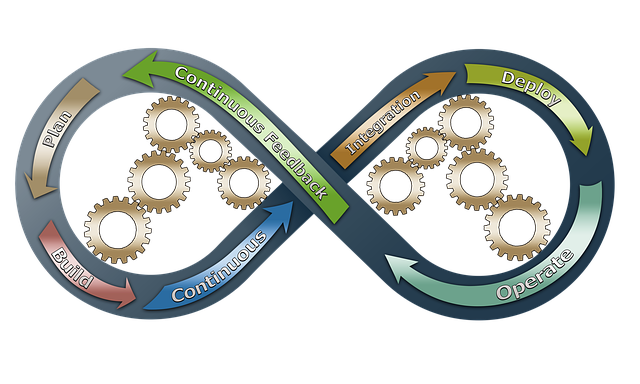

Implementing Lean Management Principles is a strategic step towards achieving streamlined and efficient workflows in any organization. Lean methodology, rooted in manufacturing excellence, focuses on minimizing waste and maximizing value through continuous improvement. The 5S training method, a cornerstone of lean management, involves sorting, setting in order, shining (cleaning), standardizing, and sustaining. This systematic approach to workplace organization ensures every process is optimized for productivity without unnecessary steps or resources.

By adopting 5S continuous improvement practices, organizations can achieve remarkable results, including improved workflow efficiency, enhanced quality control, and reduced operational costs. Process standardization becomes a cornerstone of lean management, allowing tasks to be completed in consistent, predictable ways. This not only reduces errors but also empowers employees to focus on value-added activities, fostering a culture of continuous learning and enhancement within the organization.

Workplace Organization: Streamlining Spaces

In today’s competitive business landscape, effective workplace organization is a key driver for operational efficiency and productivity gains. A systematic approach to workspace management, often achieved through 5S training and lean management principles, forms the backbone of this strategy. The 5S methodology—Sort, Set in Order, Shine, Standardize, Sustain—is a powerful tool for process standardization that promotes a tidy, efficient, and safe work environment. By implementing these practices, employees can quickly identify where improvements are needed, reducing wasted time and resources.

Workplace organization extends beyond physical spaces; it encompasses the processes and systems that dictate how work is done. Continuous improvement, fostered by 5S continuous improvement initiatives, ensures that organizations stay agile and responsive to changing market demands. Through regular reviews and adjustments, teams can identify inefficiencies, eliminate bottlenecks, and enhance overall process flow, ultimately contributing to a culture of quality and excellence.

Unlocking Efficiency: Process Standardization

Unlocking Efficiency: Process Standardization

In today’s competitive business landscape, workplace organization and process standardization are key drivers for achieving operational excellence. Lean management principles, including 5S training, provide a robust framework to streamline workflows and eliminate waste. By teaching employees the art of sorting, setting in order, shining (cleaning), standardizing, and sustaining these practices, organizations can create an environment conducive to continuous improvement.

Process standardization involves documenting and clarifying each step within a workflow, ensuring that tasks are performed consistently and efficiently. This not only enhances productivity but also fosters a culture of quality and safety. Standardized processes enable teams to collaborate more effectively, reduce errors, and adapt quickly to changing demands, ultimately positioning organizations for sustained success in the market.

Continuous Improvement: The 5S Journey Ahead

In today’s competitive business landscape, continuous improvement is not just a goal but a necessity for sustained success. The 5S methodology, rooted in lean management and workplace organization, offers a powerful framework to achieve this. This approach, which includes Sort, Set in Order, Shine, Standardize, and Sustain, provides a structured path for organizations to streamline their processes, eliminate waste, and enhance overall efficiency.

5S training equips employees with the skills needed to actively participate in process standardization, fostering a culture of ongoing improvement. By adhering to these principles, businesses can transform their workplaces into environments that are more productive, safer, and better equipped to meet evolving customer demands. Continuous 5S continuous improvement ensures that organizations remain agile, innovative, and competitive in an ever-changing market.

By integrating 5S training with lean management principles, workplace organization can be streamlined, unlocking efficiency and enhancing productivity. Process standardization ensures consistent results, enabling continuous improvement initiatives. Embracing this systematic workflow improvement approach not only optimizes current processes but also paves the way for a sustainable and thriving work environment.