The 5S methodology, rooted in lean management, transforms workplace organization through five steps: sorting, setting in order, cleaning (shining), standardizing, and sustaining. This system enhances efficiency by eliminating clutter, establishing clear processes, fostering continuous improvement, and promoting a culture of process standardization, enabling teams to focus on high-value tasks.

Tired of cluttered spaces and lost time? Discover a systematic decluttering process that transforms your environment and boosts productivity. This article explores powerful methods like the 5S Methodology and Lean Management principles to create a streamlined workspace. Learn how setting clear organization standards and embracing regular decluttering contribute to continuous improvement and process standardization. Implement these strategies for optimal workplace efficiency today!

- Understand the 5S Methodology for Decluttering

- Implement Lean Management Principles in Your Space

- Define Clear Organization Standards for Workplace Efficiency

- Foster Continuous Improvement Through Regular Decluttering

Understand the 5S Methodology for Decluttering

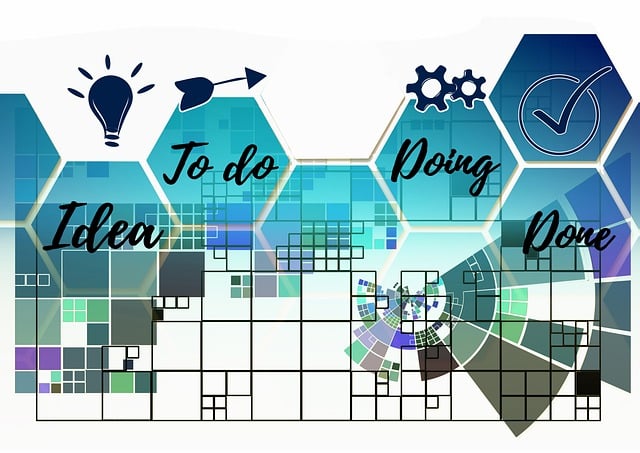

The 5S methodology is a powerful tool for achieving an organized and efficient workplace, rooted in lean management principles. It involves five simple yet effective steps: Sort, Set in Order, Shine (Clean), Standardize, and Sustain. This systematic approach to decluttering and organization is widely used in various industries for improving workflow and productivity.

By following these steps, you create a structured environment that promotes 5S continuous improvement. “Sort” involves eliminating unnecessary items, keeping only what’s essential. “Set in Order” ensures everything has its designated place, enhancing accessibility. “Shine” focuses on deep cleaning to maintain a pristine workspace. “Standardize” establishes clear processes and documentation for sustained organization. Finally, “Sustain” emphasizes ongoing maintenance and regular 5S training to prevent clutter from returning.

Implement Lean Management Principles in Your Space

Implementing Lean Management principles is a powerful way to transform your space into an organized and efficient environment. Inspired by the 5S training methodology, this approach emphasizes the importance of sorting, setting in order, shining a light on things, standardizing processes, and continually improving—a cycle known as continuous improvement.

By adopting these practices, you can achieve remarkable workplace organization. Start with identifying and eliminating unnecessary items, ensuring only essential tools and resources are present. Next, organize what remains logically and ergonomically, making tasks easier to perform. Regularly conduct reviews to maintain order and leverage process standardization techniques, like creating clear workflows and documenting procedures. This ensures consistency and makes it simpler for everyone to understand their roles in maintaining a decluttered space.

Define Clear Organization Standards for Workplace Efficiency

Establishing clear organization standards is a cornerstone of any effective systematic decluttering process, particularly in the workplace. This involves adopting principles like those taught in 5S training, which emphasizes sorting, setting in order, shining (cleaning), standardizing, and sustaining. By implementing lean management techniques, organizations can achieve optimal workplace organization that enhances efficiency and productivity.

Process standardization plays a crucial role here. Defining clear guidelines for where items should be stored, how tasks should be performed, and what constitutes an organized space ensures consistency and makes maintenance easier. This not only facilitates the 5S continuous improvement process but also empowers employees to take ownership of maintaining a tidy and efficient workspace.

Foster Continuous Improvement Through Regular Decluttering

Regular decluttering is a key component of fostering continuous improvement in any workspace. Incorporating 5S training and lean management principles into your organization’s culture can help maintain an organized environment, streamlining workflows and enhancing productivity. By making decluttering a habitual part of operations, teams can identify and eliminate waste, simplify processes, and ensure that only essential tools and resources are readily accessible.

This disciplined approach aligns with process standardization, enabling employees to focus their energy on high-value tasks. Moreover, regular decluttering sessions create an opportunity for reflection and reassessment, encouraging a mindset of continuous improvement. This methodical process, inspired by the 5S methodology’s focus on sorting, setting in order, shining (or cleaning), standardizing, and sustaining, ensures that the workplace remains optimized for efficiency and effectiveness over time.

By implementing the 5S methodology, integrating lean management principles, and establishing clear workplace organization standards, you can achieve a highly efficient and clutter-free environment. Regular decluttering practices, focused on continuous improvement, ensure that these benefits are sustained over time. Through proper training and standardization of processes, your workspace will remain organized, productive, and aligned with the principles of lean management.