Operational waste, like overproduction and inefficient workflows, hampers productivity, increases costs, and lowers morale. 5S training and lean management strategies target these inefficiencies through process standardization and continuous improvement, enhancing workplace organization, boosting quality, and customer value. This Japanese-originated method teaches employees sorting, setting in order, cleaning, standardizing, and sustaining to minimize waste, improve productivity, and foster a culture of constant refinement.

In today’s competitive business landscape, minimizing operational waste is crucial for maximizing efficiency and profitability. Understanding the root causes and impact of waste within your organization is the first step towards significant improvements. This article explores effective strategies such as 5S training for optimized workspace organization, Lean management techniques for continuous improvement, process standardization to reduce unnecessary steps, and cultivating a culture of waste minimization through established 5S principles.

- Understanding Operational Waste: Causes and Impact

- Implementing 5S Training for Efficient Workspace Organization

- Lean Management Techniques for Continuous Improvement

- Standardizing Processes to Reduce Unnecessary Steps

- Cultivating a Culture of Waste Minimization Through 5S Principles

Understanding Operational Waste: Causes and Impact

Operational waste refers to any activity or process that does not add value to a product or service. It can manifest in various forms, from excessive inventory and overproduction to inefficient workflows and poor workplace organization. Understanding these sources of waste is crucial for implementing effective strategies like 5S training and lean management.

The impact of operational waste goes beyond just financial losses. It slows down production, increases lead times, reduces productivity, and can even negatively affect employee morale. By identifying and addressing these inefficiencies through continuous improvement initiatives such as process standardization, organizations can enhance overall workplace organization, improve quality, and ultimately deliver better value to their customers.

Implementing 5S Training for Efficient Workspace Organization

Implementing 5S Training is a powerful strategy for minimizing operational waste and enhancing workplace organization. This lean management approach, rooted in Japanese manufacturing practices, focuses on creating an orderly, efficient, and safe environment. By teaching employees the principles of Sort, Set in Order, Shine (Clean), Standardize, and Sustain, organizations can achieve remarkable process standardization and continuous improvement.

5S training empowers workers to take ownership of their workspace, ensuring that every item has a designated place and purpose. This reduces time wasted searching for tools or inventory, allowing employees to focus on high-value tasks. Regular 5S practices also foster a culture of accountability, as teams regularly inspect and maintain their work areas, further streamlining operations and minimizing unnecessary waste.

Lean Management Techniques for Continuous Improvement

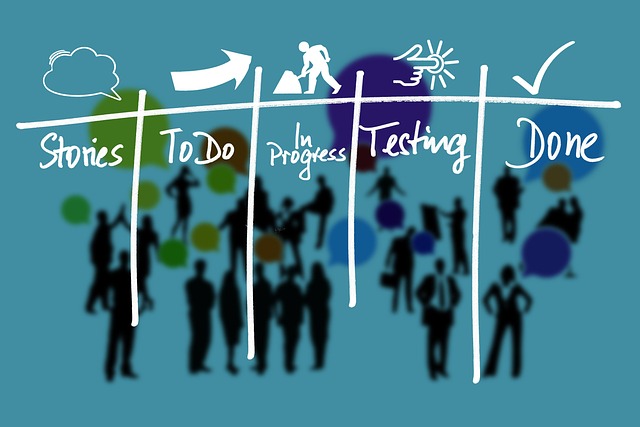

Implementing Lean Management Techniques, such as the renowned 5S training program, is a powerful strategy for operational waste minimization and driving continuous improvement in workplace organization. This Japanese management philosophy focuses on eliminating waste in all forms, from time and motion to excessive inventory and inefficient processes. By instilling discipline through 5S—Sort, Set in Order, Shine (cleanliness), Standardize, and Sustain—workplaces become highly organized and optimized for productivity.

The 5S continuous improvement methodology encourages regular audits and standardizes best practices across the organization. This ensures that every employee follows established processes, minimizing deviations and maximizing efficiency. By fostering a culture of constant refinement, lean management techniques help businesses stay agile, adapt to changing market demands, and ultimately reduce operational costs while maintaining high-quality standards.

Standardizing Processes to Reduce Unnecessary Steps

In an era where efficiency and productivity are paramount, standardizing processes is a powerful strategy to minimize operational waste. This approach, deeply rooted in lean management principles, involves streamlining workflow by eliminating unnecessary steps. Organizations can achieve this through 5S training—a methodical system for workplace organization that includes sorting, setting in order, shining (cleaning), standardizing, and sustaining. By implementing these practices, businesses not only enhance productivity but also foster a culture of continuous improvement.

Process standardization ensures that tasks are executed consistently, reducing errors and enhancing overall quality. This is achieved by clearly defining each step in a process, eliminating variations that lead to waste, and empowering employees to follow these standardized procedures. Such standardization facilitates smoother operations, allows for better resource allocation, and paves the way for continuous enhancement of work processes, ultimately contributing to a more robust and efficient organization.

Cultivating a Culture of Waste Minimization Through 5S Principles

Cultivating a culture of waste minimization starts with implementing the foundational principles of 5S training. This structured approach, deeply rooted in lean management, guides organizations to transform their workplaces into efficient, organized systems. By teaching employees to sort (seirei), set in order (seiton), shine (seiso), standardize (seiketsu), and sustain (shitsuke) their work areas, 5S fosters a mindset of continuous improvement. Each step encourages the elimination of unnecessary steps, the streamlining of processes, and the identification and reduction of operational waste.

Process standardization, a key component of 5S continuous improvement, ensures that tasks are executed consistently, minimizing errors and maximizing productivity. This standardized approach to work allows for better tracking of inefficiencies and facilitates data-driven decisions, further refining operations over time. By integrating these principles into daily practices, organizations can create an environment where waste minimization becomes a shared responsibility among all employees.

By implementing strategies such as 5S training for efficient workplace organization, lean management techniques for continuous improvement, and standardizing processes to reduce unnecessary steps, businesses can significantly minimize operational waste. Cultivating a culture of waste minimization through these proven principles ensures that every employee is committed to streamlining operations, enhancing productivity, and contributing to a more sustainable and profitable future.