The 5S Framework, a globally adopted lean management methodology, optimizes workplace organization through five stages: Sort, Set in Order, Shine, Standardize, and Sustain. This transforms cluttered spaces into streamlined environments that boost productivity. 5S training equips employees to declutter, organize, maintain, and continually enhance processes, emphasizing process standardization for sustained organization and adaptability. Implementing lean management principles dramatically improves workspace efficiency through systematic decluttering and organizational practices.

“Unclutter your life with a systematic approach! Discover the power of the 5S framework, a proven method for achieving exceptional workplace organization. This article guides you through transforming your space using Lean Management principles. Learn how to apply a structured decluttering process, from understanding the 5S methodology to implementing continuous improvement cycles.

Unlock the secrets to standardizing processes, ensuring long-term organization and productivity. Embrace a culture of efficiency with our comprehensive step-by-step guide.”

- Understanding the 5S Framework for Decluttering

- Applying Lean Management Principles in Your Workspace

- Organize Your Space: A Step-by-Step Guide

- Continuous Improvement: The 5S Cycle Unlocked

- Standardizing Processes for Long-Term Organization

Understanding the 5S Framework for Decluttering

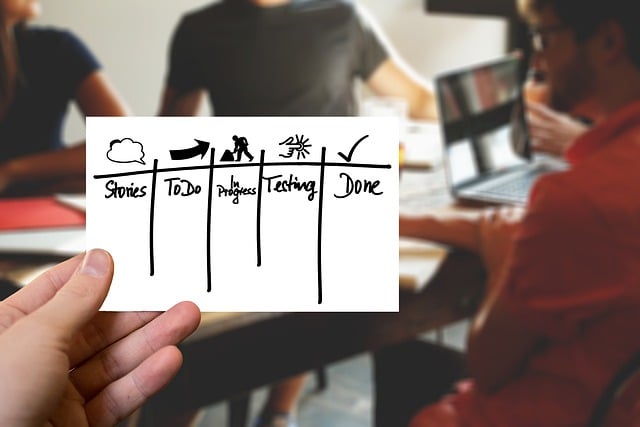

The 5S Framework is a powerful methodology for achieving efficient workplace organization and fostering a culture of continuous improvement. This lean management approach originated in Japan and has since been adapted globally, becoming an integral part of many successful decluttering practices. The framework comprises five distinct stages: Sort, Set in Order, Shine, Standardize, and Sustain. By systematically going through these steps, individuals and teams can transform cluttered spaces into streamlined environments that enhance productivity.

5S training equips employees with the skills to identify and discard unnecessary items, organize resources effectively, maintain a clean and safe workspace, and continuously improve processes. Process standardization is at the core of this method, ensuring that everyone follows consistent practices for decluttering and maintenance, leading to greater efficiency and reduced waste. This structured approach makes it easier to keep spaces organized over time and adapt to changing needs.

Applying Lean Management Principles in Your Workspace

Implementing Lean Management principles in your workspace can dramatically transform it from a cluttered mess to an efficient haven. The core concept behind Lean is eliminating waste and maximizing value, which aligns perfectly with the systematic decluttering practice. Start by introducing 5S training – Sort, Set in Order, Shine (Clean), Standardize, Sustain – to create a disciplined environment. This involves sorting through items, assigning specific places for each, regularly cleaning, standardizing processes, and continually sustaining this organized state.

Process standardization is key here; it ensures that tasks are completed efficiently and consistently. By streamlining your workflow and minimizing variations, you reduce errors and improve productivity. A well-organized workspace doesn’t just make it easier to find things when you need them; it also fosters a mental clarity that enhances creativity and focus. Embrace the power of Lean Management for a more streamlined and productive workplace.

Organize Your Space: A Step-by-Step Guide

Starting with a thorough understanding of your space and its contents is crucial for successful decluttering. Begin by documenting everything in your area using photos or an inventory list. Categorize items into functional groups, such as office supplies, paperwork, or equipment. This step facilitates identification of unnecessary duplicates or items no longer needed.

Next, employ the 5S training framework—Sort, Set in Order, Shine, Standardize, Sustain—for structured organization. Sort through your items, discarding or donating what’s no longer useful. Set them in order on shelves or desks based on frequency of use. Shine your workspace, ensuring everything has a designated place. Standardize the process by establishing clear guidelines for keeping and removing items. Finally, sustain the new order through regular maintenance and continuous improvement practices inspired by lean management principles.

Continuous Improvement: The 5S Cycle Unlocked

Incorporating a continuous improvement mindset is key to unlocking a highly organized and efficient workplace. The 5S training methodology—a lean management approach—is a powerful tool for achieving this. This system, rooted in Japanese manufacturing practices, emphasizes the importance of Sort, Set in Order, Shine (Clean), Standardize, and Sustain. By consistently applying these principles, organizations can transform their workspaces into streamlined, process-standardized environments.

5S continuous improvement encourages employees to regularly review and optimize their work areas, eliminating clutter and improving accessibility. This not only enhances productivity but also fosters a culture of accountability and engagement. As processes are standardized, teams gain a deeper understanding of their roles, leading to increased efficiency and better overall workplace organization.

Standardizing Processes for Long-Term Organization

Standardizing processes is a key aspect of implementing a successful systematic decluttering practice, especially when aiming for long-term organization in the workplace. The 5S training methodology, rooted in lean management principles, offers a structured approach to achieving this. By teaching employees to Sort, Set in Order, Shine, Standardize, and Sustain, organizations can create an environment that encourages consistent order and efficiency.

This involves defining clear processes for decluttering and organizing spaces, ensuring everyone follows the same methods. Process standardization promotes a culture of continuous improvement, where regular reviews and adjustments keep the system effective over time. It also fosters collaboration, as team members work together to maintain an organized, streamlined workplace, enhancing productivity and job satisfaction.