5S training, rooted in Japanese production methods, is a powerful tool for lean management and workplace optimization. By systematically sorting, organizing, cleaning (Sort, Set in Order, Shine), standardizing processes, and sustaining improvements, organizations achieve increased productivity, reduced waste, and minimized errors. This method leads to enhanced process standardization in manufacturing facilities, fostering continuous improvement and streamlining operations through consistent workflows and established procedures. Proven effective across diverse industries, 5S training is crucial for modern industry, benefiting both processes and employee satisfaction.

“Boosting manufacturing efficiency is a top priority for many industries. This article explores powerful strategies centered around the 5S training methodology and its profound impact on operational excellence. We’ll delve into the core principles of 5S, including understanding workspace organization and implementing lean management techniques. By examining real-world applications, we uncover how these principles drive continuous improvement and streamline operations through process standardization, ultimately revolutionizing manufacturing workflows.”

- Understanding the Core Principles of 5S Training

- Implementing Lean Management for Maximum Efficiency

- The Role of Workplace Organization in Process Standardization

- Continuous Improvement: A Key Tenet of 5S Methodology

- Streamlining Operations: Benefits of Process Standardization

- Real-World Applications: Success Stories of 5S Implementation

Understanding the Core Principles of 5S Training

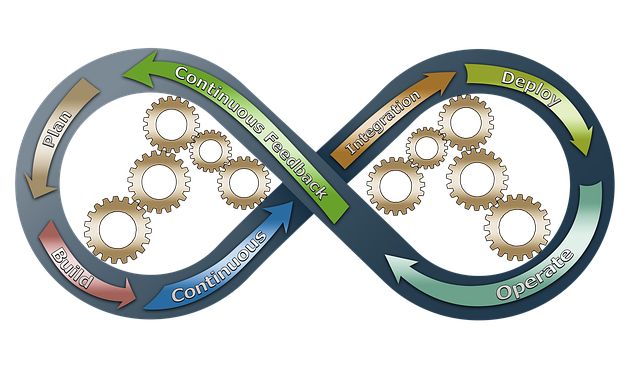

5S training is a cornerstone of lean management and workplace organization, focusing on creating an efficient and safe work environment through systematic sorting, organizing, and cleaning. This method, derived from Japanese production practices, emphasizes the importance of standardizing processes to enhance productivity and quality. The ‘S’ in 5S stands for Sort (removing unnecessary items), Set in Order (arranging tools and equipment logically), Shine (cleaning and maintaining), Standardize (establishing consistent procedures), and Sustain (continuing the cycle of improvement).

By implementing 5S principles, organizations can achieve significant gains in workflow optimization. It involves training employees to maintain a tidy, organized workspace, ensuring that every tool and material has its designated place. This approach streamlines processes, reduces waste, and minimizes errors, ultimately contributing to the overall process standardization and continuous improvement within any manufacturing facility.

Implementing Lean Management for Maximum Efficiency

Implementing Lean Management for Maximum Efficiency

In today’s competitive manufacturing landscape, embracing lean management principles is a game-changer. The foundation lies in the powerful 5S training methodology, which transforms chaotic workplaces into organized systems. This involves sorting (seiri), setting in order (seiton), shining (seiso), standardizing (seiketsu), and sustaining (shitsuke) to create an environment conducive to efficiency. By teaching employees these practices, manufacturers can achieve remarkable results in workplace organization and continuous improvement.

Lean management goes beyond 5S by focusing on process standardization. It involves streamlining every step of a manufacturing process to eliminate waste and reduce non-value-added activities. This standardized approach ensures consistency, enabling teams to work more collaboratively and effectively. As a result, manufacturers experience enhanced productivity, improved quality, and reduced lead times, solidifying their position in the market.

The Role of Workplace Organization in Process Standardization

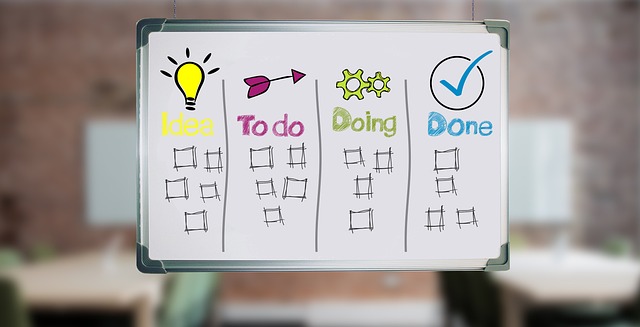

Workplace organization plays a pivotal role in achieving process standardization, which is a key tenet of lean management. The 5S training methodology—a popular and effective approach to workplace organization—encourages employees to tidy up their work areas, standardize processes, and strive for continuous improvement. By implementing 5S principles, such as sorting, setting in order, shining (cleaning), standardizing, and sustaining, organizations can create a more efficient and streamlined environment.

This structured system ensures that every aspect of the manufacturing process is optimized, from material handling to production flow. Well-organized workplaces reduce waste, minimize errors, and enhance productivity, ultimately contributing to overall process standardization. As a result, 5S continuous improvement becomes an integral part of lean management, fostering a culture of efficiency and quality in manufacturing operations.

Continuous Improvement: A Key Tenet of 5S Methodology

Continuous improvement is at the heart of the 5S methodology, one of the most powerful tools in lean management and workplace organization. This principle encourages organizations to constantly seek ways to enhance efficiency and reduce waste within their processes. By fostering a culture of continuous learning and refinement, companies can achieve exceptional levels of process standardization.

5S training equips employees with the knowledge and skills to identify inefficiencies, streamline tasks, and maintain a highly organized workplace. This disciplined approach ensures that every step of a process is scrutinized for potential improvements, leading to significant gains in productivity and quality over time.

Streamlining Operations: Benefits of Process Standardization

Streamlining operations through process standardization is a core principle of lean management and 5S training. By implementing consistent workflows and established procedures, manufacturers can significantly reduce waste and inefficiencies. Standardization ensures that every step in the production process is optimized, minimizing variations that may cause delays or errors. This approach fosters a culture of continuous improvement where employees are encouraged to identify and eliminate non-value-added activities, leading to increased productivity and enhanced quality control.

Workplace organization benefits from process standardization as it clarifies roles and responsibilities, making it easier for teams to collaborate effectively. The 5S methodology—Sort, Set in Order, Shine (Clean), Standardize, Sustain—serves as a powerful framework for achieving this. By maintaining an organized workspace and adhering to standardized processes, manufacturers can enhance safety, reduce errors, and improve overall operational efficiency. This not only benefits the manufacturing process but also contributes to a more satisfying work environment for employees.

Real-World Applications: Success Stories of 5S Implementation

The 5S method, a cornerstone of lean management and workplace organization, has proven its worth in countless real-world applications across various industries. This powerful system, comprising Sort, Set in Order, Shine (Clean), Standardize, and Sustain, offers a structured approach to creating efficient, safe, and highly organized workplaces.

Success stories abound, from manufacturing plants where 5S training and continuous improvement initiatives led to significant process standardization and increased productivity to healthcare facilities that employed these principles for enhanced patient care. By implementing 5S, organizations streamline workflows, reduce waste, and foster a culture of ongoing improvement, making it an indispensable tool in modern industry.