The Lean Workplace Philosophy, rooted in Toyota's manufacturing, optimizes operations via 5S training (Sort, Set in Order, Shine, Standardize, Sustain) and lean management principles. This system eliminates waste, enhances productivity through resource management, fosters continuous improvement, and drives business success across sectors like healthcare and retail. Process standardization ensures consistent efficiency and organized environments.

“Discover the transformative power of a lean workplace philosophy – a system designed to optimize efficiency and productivity. This comprehensive guide delves into the core principles of lean management, with a particular focus on 5S training as the cornerstone for success. Learn how streamlined workplace organization, coupled with continuous improvement initiatives like process standardization, can drive long-term success across various industries. Explore real-world applications and unlock the secrets to enhancing operational excellence.”

- Understanding Lean Workplace Philosophy: A Comprehensive Guide

- 5S Training: The Cornerstone of Lean Management

- Workplace Organization: Streamlining for Efficiency and Effectiveness

- Continuous Improvement: Embracing 5S for Long-Term Success

- Process Standardization: Creating Consistency in the Workplace

- Real-World Applications: Adopting Lean Philosophy Across Industries

Understanding Lean Workplace Philosophy: A Comprehensive Guide

The Lean Workplace Philosophy is a systematic approach to workplace optimization inspired by Toyota’s manufacturing processes. It focuses on eliminating waste, improving efficiency, and enhancing overall productivity. At its core, this philosophy emphasizes the importance of understanding and managing resources effectively, ensuring every task and process adds value to the final product or service.

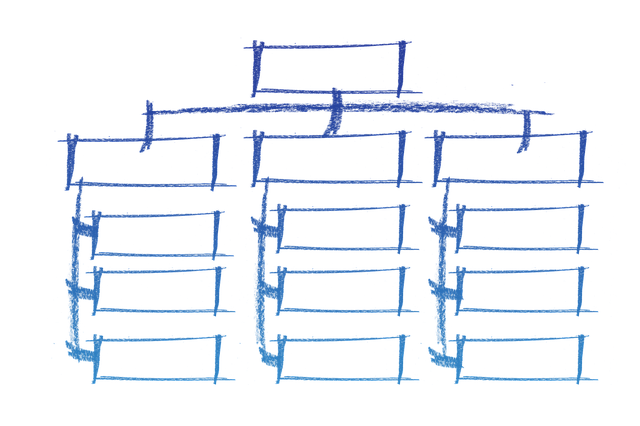

This methodology involves implementing strategies like 5S training, a system that promotes workplace organization through sorting, setting in order, shining (cleaning), standardizing, and sustaining. By adopting lean management principles, organizations can streamline their operations, reduce unnecessary steps, and create a culture of continuous improvement. Process standardization plays a crucial role in achieving this, ensuring tasks are performed consistently and efficiently across the board.

5S Training: The Cornerstone of Lean Management

5S Training is a foundational pillar within Lean Management, focusing on workplace organization and continuous improvement. This systematic approach involves five key disciplines: Sort, Set in Order, Shine (Clean), Standardize, and Sustain. By implementing 5S, organizations can achieve unparalleled efficiency and productivity through process standardization.

It begins with sorting, where unnecessary items are removed to create a clutter-free environment. Setting everything in order ensures tools and resources are easily accessible. Shining involves deep cleaning to maintain a pristine workspace. Standardization guarantees processes remain consistent, while sustaining reinforces these practices over time. This holistic training empowers employees to actively participate in improving their workplace and work processes, ultimately driving organizational success.

Workplace Organization: Streamlining for Efficiency and Effectiveness

A lean workplace philosophy emphasizes efficient and effective processes through meticulous workplace organization. This involves implementing 5S training—a methodology that stands for Sort, Set in Order, Shine (Clean), Standardize, and Sustain. By systematically organizing the workspace, teams can reduce waste, improve accessibility to tools and information, and create a safer environment.

Workplace organization is not a one-time event but an ongoing 5S continuous improvement process. Standardization of processes ensures consistency in how tasks are performed, leading to increased productivity and reduced errors. This lean management approach fosters a culture where every element of the workplace contributes to enhancing workflow efficiency, empowering employees, and ultimately driving business success.

Continuous Improvement: Embracing 5S for Long-Term Success

In the pursuit of a lean workplace, embracing continuous improvement methodologies is paramount for long-term success. One such powerful approach is the 5S system, which involves sorting, setting in order, shining (cleaning), standardizing, and sustaining. This method transforms cluttered workspaces into organized environments, enhancing efficiency and productivity. By training employees in 5S techniques, organizations can achieve a standardized work process that minimizes waste and streamlines operations.

Effective 5S continuous improvement requires commitment from all levels of the organization. It involves identifying and eliminating non-value-added activities, organizing tools and equipment for easy accessibility, and establishing clear standards for maintaining order. This disciplined approach ensures that improvements are sustained over time, creating a culture of ongoing excellence that drives business success in any industry.

Process Standardization: Creating Consistency in the Workplace

Process Standardization is a cornerstone of the lean workplace philosophy, aimed at creating consistency and efficiency in everyday operations. It involves implementing structured systems and protocols that ensure tasks are performed in a predictable and optimized manner. This approach leverages 5S training—a foundation of lean management—to organize the workspace, streamline processes, and eliminate waste. By adhering to standardized procedures, employees can focus on value-added activities, leading to improved productivity and quality.

Furthermore, process standardization facilitates continuous improvement by providing a clear framework for identifying inefficiencies and implementing enhancements. This discipline encourages regular reviews and adjustments, ensuring that the workplace remains agile and responsive to changing demands. Ultimately, it contributes to a culture of excellence where every step is measured, optimized, and aligned with the organization’s goals, fostering an environment where everyone works smarter, not harder.

Real-World Applications: Adopting Lean Philosophy Across Industries

The Lean workplace philosophy, rooted in the principles of Japanese production methods, has found its way into diverse industries worldwide. This approach, which emphasizes efficiency, waste reduction, and continuous improvement, is not limited to manufacturing; it can be successfully implemented across various sectors. For instance, 5S training, a core component of Lean, teaches employees a systematic method for organizing their workspace, similar to organizing a house or room. This simple yet powerful tool has been adapted by service industries like healthcare and hospitality to enhance workplace organization and improve patient/customer satisfaction.

Moreover, lean management principles focus on process standardization, encouraging businesses to streamline operations by identifying and eliminating non-value-added steps. Many companies have adopted these practices to reduce costs, increase productivity, and improve overall quality. The 5S continuous improvement methodology, for example, is used in retail to optimize store layouts, ensuring products are easily accessible, reducing shopping time, and enhancing the overall customer experience. This real-world application demonstrates how Lean workplace philosophy adapts and benefits organizations across diverse industries.

The lean workplace philosophy, centered around concepts like 5S training, workplace organization, and continuous improvement, offers a transformative approach to enhancing efficiency and effectiveness. By implementing process standardization, organizations across diverse industries can achieve remarkable results, streamlining operations for long-term success. Adopting these principles not only leads to increased productivity but also fosters a culture of ongoing enhancement, ensuring businesses remain competitive in today’s dynamic market.