5S training, rooted in Toyota's lean management system, is a powerful tool for transforming workplaces through organization and continuous improvement. By adhering to its five core principles (Sort, Set in Order, Shine, Standardize, Sustain), businesses eliminate waste, enhance efficiency, foster accountability, and create safer, more productive environments. This structured approach standardizes processes, streamlines operations, boosts job satisfaction, and promotes a culture of order. Implementing 5S improves workplace organization, reduces errors, enhances productivity, and adapts to changing demands. Success stories span manufacturing, warehousing, and healthcare, showcasing increased output, reduced defects, and improved patient care.

“Unleash the power of optimized workspaces with our comprehensive guide. Explore the transformative potential of 5S training and its synergy with Lean management principles. We delve into strategies for effective workplace organization, highlighting the pivotal role of continuous improvement within the 5S framework. Learn how process standardization enhances efficiency, drawing from real-world applications that have achieved remarkable success through these proven techniques.”

- Understanding the Basics of 5S Training

- Implementing Lean Management Principles

- Strategies for Effective Workplace Organization

- The Role of Continuous Improvement in 5S

- Standardizing Processes for Increased Efficiency

- Real-World Applications and Success Stories

Understanding the Basics of 5S Training

5S training is a powerful tool within the realm of lean management, focusing on workplace organization and continuous improvement. It originated in Japan as part of the Toyota Production System and has since revolutionized various industries with its simple yet effective approach. The name 5S comes from five fundamental principles: Sort, Set in Order, Shine (Clean), Standardize, and Sustain. These steps guide organizations through a structured process to eliminate waste, improve efficiency, and create a safer, more organized environment.

By implementing 5S training, businesses can achieve better process standardization and streamline their operations. It encourages employees to take ownership of their workspace, fostering a culture of order and accountability. Regular 5S continuous improvement initiatives ensure that the workplace remains efficient, with every tool and resource readily accessible, enhancing productivity and overall job satisfaction.

Implementing Lean Management Principles

Implementing Lean Management Principles is a powerful strategy to transform your workplace and elevate operational efficiency. At its core, Lean management focuses on minimizing waste while maximizing value in every process. One effective way to achieve this is through 5S training, a methodology that involves sorting, setting in order, shining (cleaning), standardizing, and sustaining these practices. This structured approach ensures that the workplace is organized, with each item having a designated purpose and place, fostering an environment conducive to improved productivity.

By integrating 5S continuous improvement into daily operations, organizations can streamline processes, reduce errors, and enhance overall workplace organization. Process standardization plays a pivotal role in this equation, ensuring that tasks are executed consistently, efficiently, and in accordance with established best practices. This, in turn, leads to increased employee engagement, reduced downtime, and better quality outputs, ultimately contributing to the long-term success and competitiveness of any business.

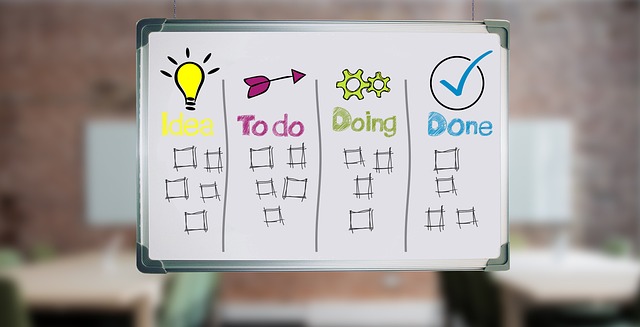

Strategies for Effective Workplace Organization

Implementing effective workplace organization strategies is key to enhancing productivity and efficiency. One powerful approach is adopting 5S training principles—a lean management technique that focuses on sorting, setting in order, shining (cleaning), standardizing, and sustaining. This method transforms chaotic workspaces into streamlined environments, ensuring every tool and resource has its place. By teaching employees the 5S methodology, companies can foster a culture of continuous improvement and maintain an organized system over time.

Process standardization plays a vital role in workplace organization. It involves creating consistent procedures for routine tasks, reducing waste, and minimizing errors. Standardized processes provide clarity and make it easier for new hires to onboard, ensuring they quickly understand their roles and responsibilities. Regular reviews and updates of these standards can further optimize the workflow, allowing businesses to adapt to changing demands while maintaining efficiency.

The Role of Continuous Improvement in 5S

The core principle of 5S lies in its ability to drive continuous improvement within any workplace. This lean management philosophy encourages organizations to constantly refine and optimize their processes, fostering a culture of efficiency and excellence. By integrating 5S training into daily operations, employees learn to identify waste, streamline workflows, and maintain meticulous organization. This discipline promotes the standardization of processes, ensuring every task is executed consistently and effectively.

Continuous improvement through 5S goes beyond initial setup. It requires regular audits and adjustments to adapt to evolving business demands. This dynamic approach ensures that the workplace remains optimized, enhancing productivity and overall job satisfaction. As processes are standardized, errors are minimized, and valuable time is saved, allowing employees to focus on value-added activities.

Standardizing Processes for Increased Efficiency

Standardizing processes is a powerful strategy for boosting workplace efficiency and productivity. This involves implementing structured methods and protocols across various tasks and operations. By adopting principles like those found in 5S training—a framework that promotes organization, sorting, shining (cleaning), standardizing, and sustaining—workplaces can create a consistent and streamlined environment. Lean management techniques complement this by focusing on eliminating waste and optimizing workflows, ensuring every step adds value.

Process standardization achieves several benefits, including improved employee morale as tasks become more predictable and manageable. It also enhances communication and collaboration since everyone follows the same procedures. Moreover, standardized processes facilitate continuous improvement initiatives, allowing for regular reviews and adjustments to stay agile and responsive to changing business demands.

Real-World Applications and Success Stories

In real-world applications, 5S training and lean management principles have proven to be game changers for numerous organizations across various industries. By implementing workplace organization strategies, companies are witnessing significant improvements in efficiency and productivity. The 5S continuous improvement methodology, which includes sorting, setting in order, shining (cleanliness), standardizing, and sustaining, has been successfully adopted in manufacturing plants, warehouses, and even office spaces. This structured approach to workplace organization ensures that every element within a workspace serves a purpose, enhancing workflow and reducing waste.

Success stories abound of businesses experiencing remarkable transformations after integrating lean management practices. For instance, many manufacturing facilities have reported increased production output and reduced defects by implementing process standardization techniques. These strategies not only streamline operations but also foster a culture of continuous improvement among employees. Additionally, healthcare institutions have leveraged 5S training to optimize patient care areas, leading to improved safety measures and enhanced patient satisfaction.