5S training, a lean management technique, revolutionizes factory floors by promoting workplace organization through sorting, ordering, cleaning, standardizing, and maintaining. This system reduces errors, boosts productivity, and cultivates efficiency. Combining 5S with continuous improvement initiatives streamlines processes, enhances throughput, and fosters a culture of constant refinement in today's competitive manufacturing sector.

“Unleash maximum efficiency in your factory floor with comprehensive strategies. This guide delves into essential components of optimization, starting with a foundational understanding of workplace organization and process standardization. We explore the transformative power of 5S training, a step-by-step method for streamlining spaces and workflows. Additionally, discover how Lean Management principles can revolutionize operations by eliminating waste and enhancing productivity. Learn how to sustain optimization through continuous 5S improvement.”

- Understanding Factory Floor Basics: Workplace Organization 101

- Implementing 5S Training: A Step-by-Step Guide to Success

- Lean Management Principles: Streamlining Processes for Efficiency

- Continuous Improvement with 5S: Sustaining Optimization Over Time

Understanding Factory Floor Basics: Workplace Organization 101

Factory floor optimization starts with a solid understanding of workplace organization. At its core, this involves implementing principles like 5S training—a system that emphasizes sorting, setting in order, shining (cleaning), standardizing, and sustaining. This method transforms chaotic spaces into streamlined environments, enhancing productivity and efficiency.

A well-organized factory floor benefits from lean management practices that focus on process standardization. By removing waste and streamlining workflows, businesses can improve throughput while reducing errors. Regular 5S continuous improvement initiatives ensure the workplace remains optimized, fostering a culture of efficiency that drives success in today’s competitive manufacturing landscape.

Implementing 5S Training: A Step-by-Step Guide to Success

Implementing 5S Training is a powerful strategy for transforming factory floors into lean, efficient workplaces. This Japanese management philosophy focuses on sorting, setting in order, shining (cleaning), standardizing, and sustaining—the core principles of 5S. To achieve success, begin by educating your workforce on these concepts. Start with an introduction to the 5S methodology and its benefits for improving productivity and quality. Then, break down each step into actionable tasks.

Organize training sessions that include hands-on exercises, such as sorting through tools and materials to identify what’s essential and discard unnecessary items. Encourage team members to create standardized work procedures and visual management systems, like color-coded labels and signs, to ensure consistent processes. Emphasize the importance of regular maintenance and continuous improvement, fostering a culture where every employee takes pride in their organized workspace.

Lean Management Principles: Streamlining Processes for Efficiency

Factory floor optimization often revolves around implementing Lean Management Principles to streamline processes and boost efficiency. At the heart of this approach lies 5S training—a system that emphasizes workplace organization through sorting, setting in order, shining (cleaning), standardizing, and sustaining. This disciplined methodology ensures every tool, material, and machine has its designated place, accessible at a moment’s notice, thereby reducing wasted time and resources.

Process standardization is another key pillar of Lean Management. By documenting and optimizing workflows, companies can identify inefficiencies and implement continuous improvement strategies. Standardized processes not only enhance productivity but also ensure quality consistency, as employees follow clearly defined steps, minimizing errors and maximizing output. This data-driven approach allows for ongoing adjustments, fostering a culture of constant refinement and excellence on the factory floor.

Continuous Improvement with 5S: Sustaining Optimization Over Time

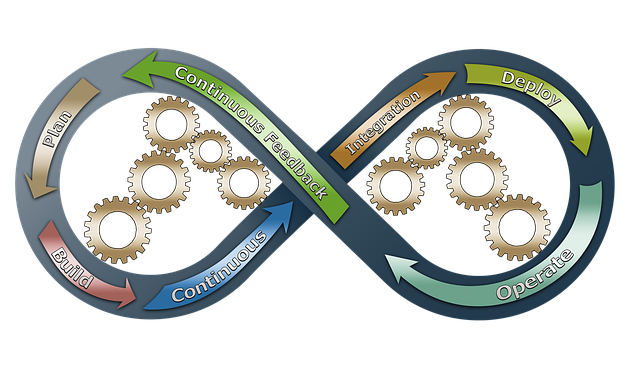

Continuous Improvement with 5S is a lean management approach that focuses on workplace organization and process standardization. By implementing 5S training, factories can sustain optimization over time, ensuring efficient workflows and reduced waste. This method involves sorting, setting in order, shining (cleaning), standardizing, and sustaining—a systematic framework that encourages regular assessments and adjustments to maintain a high level of productivity.

The 5S methodology promotes a culture of continuous learning and enhancement. Regular 5S audits ensure that standards are maintained, identifying areas for further improvement. This iterative process allows factories to adapt to changing demands, ensuring their operations remain efficient, effective, and competitive in the market.

Factory floor optimization is a multifaceted approach that combines strong workplace organization, like the principles of 5S training, with efficient process standardization and lean management. By implementing these strategies, businesses can achieve significant improvements in productivity and efficiency. Continuous improvement through 5S ensures that optimizations are sustained over time, creating a streamlined environment that benefits both employees and operations. Remember that a well-organized factory floor is the backbone of any successful manufacturing operation.