5S training, rooted in lean management, optimizes manufacturing processes through sorting, setting in order, cleaning (shining), standardizing, and sustaining. This Japanese methodology enhances productivity, reduces waste, and fosters a culture of efficiency by empowering employees to maintain organized, standardized work environments. Regular 5S continuous improvement practices ensure adaptability to market demands, driving sustained success in modern manufacturing.

In today’s competitive manufacturing landscape, adopting best practices is crucial for staying ahead. This article explores five key methodologies that form the backbone of efficient production processes: 5S Training, Lean Management, Workplace Organization, 5S Continuous Improvement, and Process Standardization. Each strategy offers proven techniques to streamline operations, enhance productivity, and ensure consistent quality, ultimately driving success in a dynamic market.

- 5S Training: Laying the Foundation for Efficiency

- Lean Management: Streamlining Operations for Success

- Workplace Organization: Maximizing Space and Productivity

- Continuous Improvement: Evolving with 5S Methodologies

- Process Standardization: Ensuring Consistency and Quality

5S Training: Laying the Foundation for Efficiency

5S Training plays a pivotal role in establishing an efficient manufacturing process by fostering workplace organization and lean management principles. This systematic approach, rooted in Japanese production methods, involves five key elements: Sort, Set in Order, Shine (Clean), Standardize, and Sustain. By training employees to adhere to these practices, manufacturers can achieve significant improvements in productivity and quality control.

5S continuous improvement drives process standardization, ensuring that every step of the manufacturing workflow is optimized and streamlined. This not only reduces waste but also enhances overall workplace efficiency. A well-organized and clean environment, achieved through the ‘Shine’ component, improves safety and promotes a culture of quality. Regular 5S training sessions empower employees to take ownership of maintaining these standards, contributing to sustained success in manufacturing operations.

Lean Management: Streamlining Operations for Success

Lean Management is a powerful approach that transforms manufacturing processes by eliminating waste and streamlining operations. At its core, it emphasizes workplace organization through the 5S training method—Sort, Set in Order, Shine (Clean), Standardize, and Sustain. This disciplined system ensures every step of the production line is optimized for efficiency and effectiveness. By implementing 5S continuous improvement practices, manufacturers can achieve remarkable results, including enhanced productivity, reduced defects, and improved overall workplace organization.

Process standardization plays a vital role in lean management, enabling teams to work in harmony with clearly defined procedures. This not only facilitates smoother workflows but also empowers employees to identify and address inefficiencies proactively. The synergy created through 5S training and process standardization acts as a catalyst for sustained success, making it an indispensable best practice for modern manufacturing.

Workplace Organization: Maximizing Space and Productivity

A well-organized workplace is a key driver for both efficiency and productivity in manufacturing settings. Implementing 5S training principles—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—can dramatically transform the factory floor. This continuous improvement methodology encourages workers to maintain an orderly environment, streamlining processes and reducing waste. By fostering a culture of process standardization, lean management techniques can be effectively deployed to maximize space utilization.

Workplace organization goes beyond aesthetics; it directly impacts operational flow. Efficient use of space ensures that equipment, materials, and personnel are strategically positioned, minimizing movement and maximizing output. Regular 5S audits and continuous improvement initiatives reinforce these benefits, allowing manufacturers to stay agile and competitive in a dynamic market.

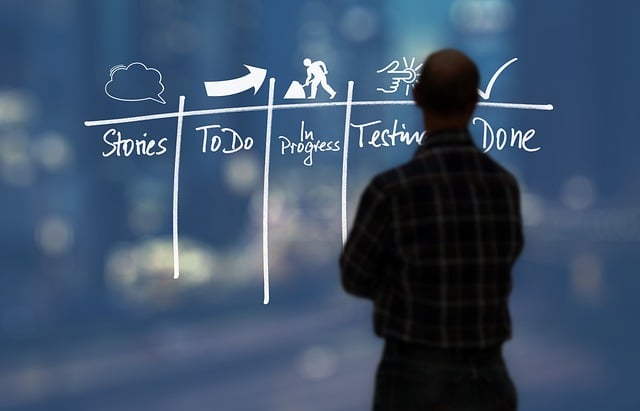

Continuous Improvement: Evolving with 5S Methodologies

In today’s competitive manufacturing landscape, embracing continuous improvement is vital for staying ahead. One highly effective approach is leveraging 5S methodologies, rooted in lean management principles, to enhance workplace organization and process standardization. This disciplined system, encompassing Sort, Set in Order, Shine (Clean), Standardize, and Sustain, serves as a game-changer for streamlining operations and fostering a culture of excellence.

5S training empowers employees to actively participate in identifying and eliminating waste, reorganizing work areas, and establishing consistent procedures. By implementing these practices, manufacturers can achieve significant benefits, including increased efficiency, reduced downtime, and improved product quality. Continuous improvement becomes an integral part of the organizational DNA, ensuring that processes remain optimized and adaptable to evolving market demands.

Process Standardization: Ensuring Consistency and Quality

Process Standardization is a cornerstone of modern manufacturing best practices, focusing on creating consistent and high-quality outputs through structured workflows. This involves implementing systems like 5S training and lean management to optimize the workplace organization. The 5S method—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—is a continuous improvement initiative that promotes a tidy, efficient workspace. By ensuring every step of the production process is standardized, manufacturers can minimize errors and waste, thereby enhancing overall productivity.

Furthermore, lean management principles emphasize the elimination of non-value-added activities, which aligns with process standardization. This means streamlining operations to deliver products faster and more efficiently while maintaining or improving quality standards. Regular reviews and adjustments are crucial to sustaining this standardized approach, ensuring that the manufacturing process remains agile and responsive to evolving market demands.

By implementing best practices like 5S training, lean management, effective workplace organization, and embracing continuous improvement through 5S methodologies, businesses can achieve exceptional efficiency. Process standardization ensures that these improvements are consistently applied, leading to enhanced productivity, quality, and overall operational excellence. These strategies, when integrated into a comprehensive manufacturing strategy, create a robust foundation for success in today’s competitive market.