Ergonomic workspace design leverages 5S training, a lean management principle from Japanese manufacturing, for significant gains in productivity and employee satisfaction. The 5S framework (Sort, Set in Order, Shine, Standardize, Sustain) promotes decluttering, logical item arrangement, regular cleaning, consistent guidelines, and ongoing maintenance. Implementation leads to reduced strain, improved efficiency, and operational excellence. Regular audits, employee involvement, and digital tools enhance these benefits, fostering a culture of ergonomic excellence and continuous improvement.

In today’s digital age, the design of our workspaces plays a pivotal role in shaping employee productivity, satisfaction, and overall well-being. With remote work becoming the new norm, creating ergonomic and efficient environments is more crucial than ever. However, many organizations struggle with workspace optimization, leading to inefficiencies and potential health risks for their workforce. This article delves into the transformative power of ergonomic design principles, particularly highlighting the integration of 5S training and lean management techniques as a comprehensive solution. By implementing these strategies, including workplace organization and continuous improvement, businesses can foster a productive atmosphere that enhances employee performance and reduces potential injuries.

- Understanding Ergonomic Principles for Workspace Design

- Implementing 5S Training: A Foundation for Lean Management

- Workplace Organization: Tools & Techniques for Efficiency

- Continuous Improvement with 5S: Sustaining Optimal Workspace Design

Understanding Ergonomic Principles for Workspace Design

Ergonomic workspace design begins with a profound understanding of ergonomic principles—a science aimed at optimizing human well-being and performance. At its core, this involves creating environments that facilitate efficient, comfortable, and safe work practices. A key principle is maintaining neutral postures to prevent strain, with appropriate support for the back, neck, and wrists. Adjustable furniture, such as sit-stand desks or ergonomic chairs, plays a vital role in enabling workers to assume these neutral positions throughout their shifts.

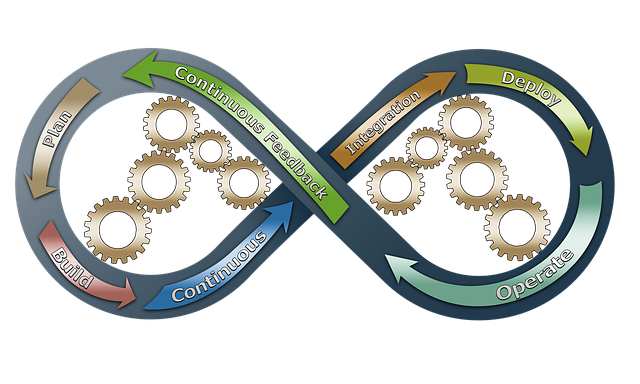

Incorporating lean management principles, including 5S training and continuous improvement methodologies like 5S continuous improvement, can significantly enhance ergonomic design. 5S—a Japanese organization method—teaches the importance of sorting, setting in order, shining (cleaning), standardizing, and sustaining these practices. This systematic approach to workplace organization not only promotes efficiency but also ensures that ergonomic considerations are built into every step of the work process, from task planning to equipment placement. For instance, a well-organized workstation with easily accessible tools can reduce unnecessary movements, thereby minimizing musculoskeletal stress.

Expert recommendations emphasize the importance of customizing workstations based on individual needs and tasks. This personalized approach involves adjusting factors like desk height, chair tilt, keyboard positioning, and monitor placement. A simple example is ensuring that computer monitors are at eye level to prevent neck strain. Data from various studies supports these practices; for instance, a research review found that ergonomic interventions significantly reduced lower back pain among office workers. Additionally, integrating regular breaks and encouraging good posture habits through training sessions can further enhance overall workplace ergonomics.

Implementing 5S Training: A Foundation for Lean Management

Ergonomic workspace design is not just about comfortable chairs and standing desks; it involves a holistic approach to creating environments that enhance productivity, reduce strain, and promote well-being. One powerful tool in this arsenal is 5S training, rooted in Lean management principles. This method, which includes sorting, setting in order, shining (cleaning), standardizing, and sustaining, serves as a foundation for streamlining workflows and optimizing workspace organization.

By implementing 5S training, organizations can achieve significant improvements in workplace efficiency and employee satisfaction. For instance, a study by McKinsey found that companies adopting Lean practices experienced up to 30% increases in productivity and reductions in waste. In the context of 5S, sorting involves eliminating unnecessary items from work areas, setting in order ensures everything has its place, shining emphasizes regular cleaning for hygiene and maintenance, standardizing establishes consistent processes, and sustaining fosters continuous improvement through regular practice and commitment.

Practical application begins with a thorough audit of existing workspace layouts and processes. Identify areas of congestion, redundant equipment, or cluttered workbenches. For example, a manufacturing facility might discover that disorganized inventory storage leads to frequent delays during production shifts. Once identified, these issues can be addressed through systematic sorting and reorganizing. Standardization comes into play by implementing clear guidelines for future maintenance and ensuring everyone follows the same procedures. Regular 5S audits and continuous improvement exercises help sustain these gains over time, adapting as the workplace evolves.

Expert advice emphasizes involving employees at all levels in the 5S process. Buy-in from the workforce ensures a more sustainable and effective implementation. Training sessions should be conducted regularly to refresh knowledge and address emerging challenges. By integrating 5S training into the corporate culture, organizations can create environments that not only support ergonomic principles but also drive operational excellence and foster a sense of ownership among employees.

Workplace Organization: Tools & Techniques for Efficiency

Ergonomic workspace design goes beyond physical adjustments; it encompasses a holistic approach to workplace organization, where efficient systems and streamlined processes contribute to productivity gains and employee well-being. A key component in this strategy is implementing robust tools and techniques for maintaining a structured environment. Drawing from methodologies such as 5S training and lean management, organizations can achieve remarkable results in enhancing both workflow and job satisfaction.

The 5S framework—Sort, Set in Order, Shine, Standardize, Sustain—serves as a powerful model for workplace organization. ‘Sort’ involves categorizing and removing unnecessary items, eliminating clutter. ‘Set in Order’ ensures that tools and equipment are arranged logically, making tasks more accessible. ‘Shine’ prompts regular cleaning to maintain an aesthetic, sanitary space. ‘Standardize’ establishes consistent practices, while ‘Sustain’ emphasizes continuous improvement, fostering a culture of organization and efficiency. For instance, a manufacturing floor utilizing 5S principles can witness reduced setup times and improved product quality, translating into significant cost savings over time.

Integrating lean management principles complements the 5S approach by focusing on process standardization and elimination of waste. This involves analyzing each step in a workflow to identify inefficiencies, which can then be streamlined or eliminated. By standardizing processes, organizations naturally foster a sense of order and predictability, enabling employees to focus on value-added activities. For example, implementing standardized procedures for document management can significantly reduce time spent searching for files, allowing staff to dedicate more attention to their core responsibilities. Regular 5S continuous improvement initiatives, combined with lean management techniques, create an environment where workplace organization becomes a way of life, driving operational excellence and employee engagement.

Continuous Improvement with 5S: Sustaining Optimal Workspace Design

Ergonomic workspace design is not a one-time endeavor but an ongoing process of continuous improvement. One proven methodology for sustaining optimal workspace design is the implementation of 5S, a lean management principle derived from Japanese manufacturing practices. The 5S framework—Sort, Set in Order, Shine, Standardize, Sustain—offers a systematic approach to workplace organization that goes beyond initial setup.

The first step, Sort, involves decluttering and categorizing items based on their utility. This process ensures only essential tools and equipment are present, reducing distractions and clutter. Subsequently, Set in Order organizes these items in a logical sequence, promoting efficient workflow. Shine mandates regular cleaning to maintain hygiene and visibility, crucial for ergonomic effectiveness. Standardize establishes clear guidelines and processes, ensuring consistent organization across shifts and time. Finally, Sustain emphasizes ongoing maintenance and the integration of 5S principles into daily routines, making it a natural part of workplace culture.

For instance, a manufacturing plant utilizing 5S training reported a 20% increase in productivity within six months, attributed to reduced setup times and improved access to tools. This success underscores the power of continuous improvement through 5S, demonstrating its potential to transform work environments not just once but continually, fostering a culture of efficiency and ergonomic excellence. Regular 5S audits, employee involvement in process improvement, and leveraging digital tools for standardization can further enhance these benefits.

By integrating ergonomic principles with strategies like 5S training and lean management, organizations can significantly enhance workplace organization and efficiency. The article has highlighted the crucial role of understanding human factors in design, implementing structured systems through 5S, and continuously improving workspace layouts. Key takeaways include the value of process standardization, which naturally flows from 5S training, for maintaining a streamlined and optimized environment. Additionally, recognizing the symbiotic relationship between workplace organization and employee productivity is essential. Moving forward, adopting a culture of continuous improvement, driven by the principles outlined here, can lead to substantial gains in both operational efficiency and overall job satisfaction.