Implementing 5S training—a lean management framework combining workplace organization techniques—empowers employees to maintain high sanitation standards through sorting, setting in order, cleaning (shining), standardizing, and sustaining. This methodology reduces downtime, enhances productivity, and improves health & safety, as seen in various sectors. Continuous improvement based on regular 5S audits and data-driven decision making ensures sustained cleanliness and operational efficiency. By integrating structured methods with employee engagement, organizations can achieve exceptional hygiene standards benefiting operations and occupant well-being.

Maintaining facility cleanliness is a cornerstone of any successful operation, fostering productivity, enhancing employee well-being, and projecting a professional image. However, achieving and maintaining high standards can be challenging, given the dynamic nature of work environments. This article delves into an authoritative strategy that combines 5S training, lean management principles, and workplace organization to drive continuous improvement in facility cleanliness. By exploring process standardization and a culture of order, this approach ensures sustainability, efficiency, and a safer, more enjoyable workspace for all.

- Establish a Cleanliness Culture: Laying the Foundation

- Implement 5S Training for Effective Organization

- Lean Management: Optimizing Processes for Efficiency

- Continuous Improvement: Sustaining a Hygienic Environment

Establish a Cleanliness Culture: Laying the Foundation

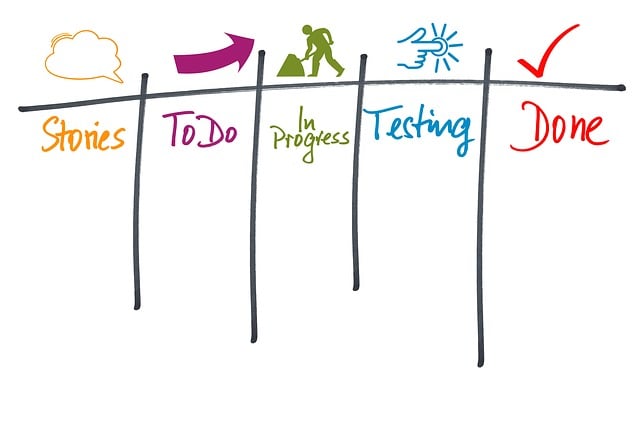

Creating a culture of cleanliness within facilities goes beyond routine cleaning tasks. It’s about fostering an environment where every employee understands, embraces, and actively contributes to maintaining high sanitation standards. This begins with establishing a strong foundation through a comprehensive training program that combines lean management principles with workplace organization techniques. Implementing the 5S methodology—sort, set in order, shine (clean), standardise, sustain—serves as a powerful framework for achieving this goal.

The 5S training process starts by teaching employees to sort through workspace items, eliminating unnecessary ones and streamlining essential tools and materials. This reduces clutter, making it easier to maintain order. Following sorting, spaces are set in order, with designated areas for specific tasks or objects, ensuring everyone knows where to find what they need. The ‘shine’ component involves regular cleaning and maintenance routines, encouraging a culture of immediate attention to mess or dirt. Through continuous improvement practices, based on the 5S framework, employees learn to identify inefficiencies and implement process standardization, naturally leading to more consistent cleanliness levels.

For instance, a manufacturing facility adopted 5S training with remarkable results. They reported a 30% reduction in downtime due to equipment obstructions caused by disorganized workspaces within six months. This efficiency gain directly translated into increased productivity and reduced costs. Moreover, employee satisfaction surveys revealed heightened morale, as staff took pride in their organized, clean workstations. By integrating 5S training into facility management strategies, organizations can create a culture that prioritizes cleanliness, leading to improved operational efficiency and enhanced work environments.

Implement 5S Training for Effective Organization

The implementation of 5S training is a powerful strategy for achieving exceptional facility cleanliness and enhancing overall workplace organization. This method, deeply rooted in lean management principles, empowers employees to transform their work environments into models of efficiency and order. By adopting 5S—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—organisations can create a culture of continuous improvement that drives sustained cleanliness and productivity gains.

At its core, 5S training focuses on process standardization, encouraging employees to visually organise their workspace, eliminate waste, and establish consistent cleaning routines. For instance, a manufacturing floor might employ coloured labels and signs to designate specific areas for raw materials, work-in-progress, and finished goods, streamlining production flows. This visual management approach not only enhances productivity but also makes it easier to identify and rectify cleanliness issues promptly. Data from studies indicate that well-organised workplaces can reduce time wasted searching for tools and supplies by up to 30%, freeing up employee time for value-added tasks.

Expert recommendations highlight the importance of regular 5S audits and continuous improvement cycles. These activities ensure that standards are maintained, identified areas for improvement are addressed, and any deviations from established practices are rectified promptly. For instance, a weekly 5S review might uncover inefficiencies in inventory management or cleaning protocols, prompting targeted initiatives to optimise these processes. This cyclical approach fosters a culture of constant refinement, where every employee plays an active role in driving workplace excellence and maintaining high cleanliness standards.

Lean Management: Optimizing Processes for Efficiency

Cleanliness in facilities is not merely an aesthetic concern; it’s a cornerstone of operational excellence, directly impacting employee productivity, health, and safety, as well as customer satisfaction. Lean Management, a proven methodology for optimizing processes, plays a pivotal role in achieving and maintaining facility cleanliness. At its core, lean management emphasizes the elimination of waste, streamlining processes, and enhancing overall efficiency. This approach is beautifully encapsulated by the Japanese concept of 5S—a system that includes sorting, setting in order, shining (cleaning), standardizing, and sustaining—which forms the backbone of effective workplace organization and continuous improvement.

Implementing lean management principles begins with comprehensive 5S training, empowering employees to take an active role in facility maintenance. For instance, a manufacturing plant utilizing 5S found that organized work stations reduced downtime by 20% as workers could quickly access tools and materials. Process standardization is another key lever; establishing clear protocols for cleaning and maintaining spaces ensures consistency and minimizes errors. A healthcare facility adopting these practices reported a 35% decrease in patient-acquired infections, underscoring the profound impact of streamlined, clean environments.

Continuous improvement is inherent in lean management, encouraging regular audits and adjustments to maintain optimal cleanliness standards. This iterative process involves tracking key performance indicators (KPIs), such as time taken for cleaning tasks or incidence rates of hygiene-related issues. Data-driven insights enable facility managers to make informed decisions, continually refining processes for maximum efficiency. For example, a retail store analyzed its cleaning routines and introduced automated mopping systems in high-traffic areas, resulting in a 15% increase in overall cleanliness ratings without significantly increasing labor costs.

Continuous Improvement: Sustaining a Hygienic Environment

Maintaining a hygienic environment in facilities is not merely a matter of routine cleaning; it’s a strategic endeavor that demands continuous improvement. The 5S training methodology—a cornerstone of lean management—offers a structured approach to workplace organization, enabling natural process standardization. By implementing 5S principles—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—organizations can create an environment conducive to optimal health and productivity.

Continuous improvement in facility cleanliness involves fostering a culture where every employee takes pride in their role. Regular training sessions on 5S, coupled with lean management principles, empower staff to identify inefficiencies and implement practical solutions. For instance, a manufacturing plant that employs 5S found that organized workstations reduced downtime by 20%, while a healthcare facility witnessed improved patient outcomes after implementing standardized cleaning protocols. Data from these real-world applications underscores the significance of continuous improvement strategies in enhancing cleanliness and efficiency.

Moreover, integrating 5S training with lean management principles facilitates systematic changes. Process standardization ensures that cleaning procedures are not just effective but also consistent across different shifts and departments. Regular audits and feedback loops, essential components of continuous improvement, help identify areas needing enhancement. For example, a retail store conducted periodic checks using visual aids, enabling them to address issues like misplaced inventory and unclean rest rooms promptly. This proactive approach ensures that the facility maintains a high level of cleanliness without overextending resources.

To sustain these efforts, organizations should encourage open communication and provide opportunities for employees to contribute ideas. Regular training refreshers, performance metrics tied to cleanliness goals, and recognition programs can reinforce the importance of hygiene. By adopting a holistic approach that combines structured methodologies with employee engagement, facilities can achieve and maintain exceptional cleanliness standards, benefiting both their operations and the well-being of those who occupy them.

By seamlessly integrating a strong cleanliness culture, comprehensive 5S training, efficient lean management strategies, and continuous 5S continuous improvement, organizations can naturally achieve exceptional workplace organization. These evidence-based practices facilitate process standardization, optimizing every step for efficiency and hygiene. Embracing these methods not only enhances operational excellence but also ensures a safe, productive, and healthy environment for all. This authoritative article equips readers with the tools to transform their facilities into models of cleanliness and productivity.