The 5S Continuous Improvement framework, rooted in lean management, offers a structured approach to workplace organization. Key components include sorting, setting in order, cleaning (shining), standardizing, and sustaining. Successful implementation requires strategic planning, top-down commitment, regular audits, employee involvement, and continuous education. This methodology has proven to reduce waste by up to 30%, boost productivity, enhance efficiency, and foster an environmentally conscious culture, with manufacturing plants reporting significant gains.

In today’s competitive business landscape, workplace sustainability initiatives are not just a moral imperative but a strategic necessity. The pressure to minimize environmental impact and maximize operational efficiency is mounting, demanding innovative solutions from forward-thinking organizations. This article delves into the transformative power of integrating 5S training and lean management principles as a robust framework for sustainable workplace organization. By exploring these methodologies, we offer a proven approach to process standardization, continuous improvement, and enhanced productivity, naturally fostering a greener, more efficient operations environment.

- Implementing 5S Training for Efficient Workplace Organization

- Lean Management: Streamlining Processes for Continuous Improvement

- Cultivating Sustainable Practices through 5S Continuous Improvement

Implementing 5S Training for Efficient Workplace Organization

The implementation of 5S training as a cornerstone of workplace organization initiatives has gained significant traction within modern organizations, driven by the need for enhanced efficiency and productivity. Rooted in lean management principles, 5S—a methodology comprising Sort, Set in Order, Shine (Clean), Standardize, and Sustain—offers a structured approach to process standardization. This system promotes an organized, safe, and efficient workplace, facilitating smoother workflows and improved employee morale.

A practical example of 5S training in action can be observed in manufacturing plants where its application has led to notable results. A study by the Lean Management Institute revealed that companies implementing 5S practices experienced an average 20% reduction in waste and a 15% increase in productivity over a two-year period. This success stems from the system’s ability to identify and eliminate unnecessary steps, reduce search times for tools and materials, and foster a culture of continuous improvement. Each “S” stage builds upon the previous one, naturally encouraging ongoing evaluation and refinement of workplace processes.

However, successful integration requires strategic planning and buy-in from all levels of the organization. Managers should initiate training by assessing the current state of workplace organization and identifying areas for improvement. Customizing the 5S framework to fit specific departmental needs is crucial. Once implemented, regular audits and team involvement in continuous improvement initiatives ensure sustained momentum. By fostering a culture where every employee takes pride in their role within the standardized system, organizations can achieve long-term gains in efficiency and workplace satisfaction.

Lean Management: Streamlining Processes for Continuous Improvement

Lean Management, rooted in Japanese manufacturing principles, offers a powerful framework for workplace sustainability initiatives. At its core, this methodology emphasizes eliminating waste and optimizing processes through continuous improvement. Organizations adopting lean practices, such as 5S training, not only enhance operational efficiency but also cultivate an environment conducive to environmental stewardship. The 5S method—Sort, Set in Order, Shine (Clean), Standardize, Sustain—serves as a structured approach to workplace organization. By systematically categorizing and arranging tools, equipment, and materials, lean management ensures that resources are accessible, reducing unnecessary movement and minimizing energy consumption.

Implementing lean principles involves a holistic review of existing processes. This entails identifying inefficiencies, bottlenecks, and areas prone to errors or waste. For instance, a manufacturing facility might employ 5S continuous improvement techniques to streamline its production line. By implementing standardized procedures for each step, from material handling to assembly, the company can reduce scrap rates, enhance product quality, and cut down on energy usage. Data-driven insights play a pivotal role in this transformation; tracking key performance indicators (KPIs) allows organizations to quantify improvements, set achievable targets, and make data-informed adjustments.

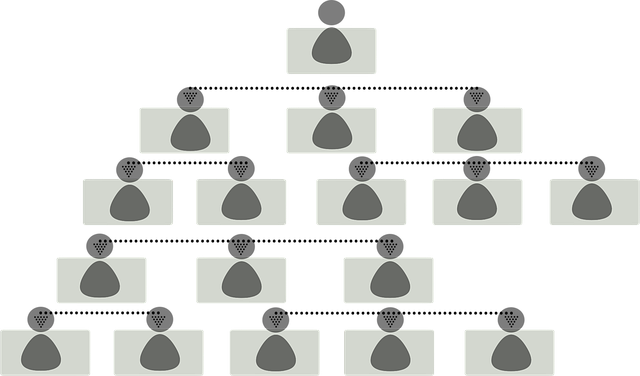

Practical application of lean management requires a dedicated workforce. Training programs, such as 5S training workshops, equip employees with the knowledge and skills needed to actively participate in process improvement initiatives. These sessions focus on fostering a culture of continuous learning and problem-solving. For instance, a retail store might conduct 5S training to optimize its inventory management system. Employees learn to organize stock rooms, implement efficient picking routes, and standardize documentation, leading to reduced out-of-stocks, improved customer satisfaction, and lower operational costs. Expert advice emphasizes that successful lean implementations involve top-down commitment and bottom-up collaboration, ensuring that every team member understands their role in driving sustainable organizational change.

Cultivating Sustainable Practices through 5S Continuous Improvement

In today’s business landscape, workplace sustainability initiatives are not just a moral imperative but also a strategic necessity. Among various approaches, cultivating sustainable practices through 5S Continuous Improvement offers a robust framework for enhancing efficiency, reducing waste, and fostering an environmentally conscious culture. The 5S methodology—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—is deeply rooted in lean management principles, focusing on workplace organization and process standardization. This systematic approach not only transforms physical spaces but also mindsets, encouraging employees to become active participants in sustainability efforts.

For instance, a manufacturing company utilizing 5S training found that implementing these practices led to significant reductions in energy consumption and material waste. By systematically sorting and organizing production lines, they identified and eliminated non-value-added steps, resulting in improved workflow efficiency. Moreover, regular “shining” or cleaning sessions not only maintain a hygienic environment but also create a culture of accountability where employees naturally prioritize cleanliness and sustainability. Process standardization, achieved through continuous improvement cycles, ensures that sustainable practices become embedded in operational norms, even as the company expands or introduces new products.

The success of 5S Continuous Improvement lies in its ability to align with business objectives while promoting environmental stewardship. Effective 5S training equips employees with the skills to identify and address inefficiencies, fostering a lean management mindset that drives continuous improvement. Data from various studies indicates that organizations adopting these practices can achieve up to 30% reduction in waste and operational costs within the first year. However, successful implementation demands commitment at all levels, regular audits, and ongoing education. Managers must be champions of change, regularly reviewing progress and encouraging feedback from employees. By integrating sustainability into the DNA of the organization, companies not only contribute to a greener future but also enhance their competitive edge in a rapidly evolving market.

By integrating 5S training with lean management principles, organizations can achieve remarkable workplace sustainability initiatives. The key insights from this article underscore the power of efficient workplace organization through 5S continuous improvement, which naturally drives process standardization. This synergistic approach not only streamlines operations for continuous improvement but also cultivates sustainable practices that are vital for long-term success. Readers can immediately apply these strategies to enhance productivity, reduce waste, and foster a culture of sustainability, making their workplaces more organized, efficient, and resilient.