5S training, rooted in lean management, offers a systematic approach to workplace optimization through sorting, setting in order, cleaning, standardizing, and sustaining. This method yields significant gains in productivity, quality, and employee satisfaction, as seen in case studies showing up to 20% production efficiency increases. Organizations like Toyota attribute their success to Lean principles. Standardization enhances efficiency, reduces errors, boosts throughput, and lowers costs by up to 20%. A culture of continuous improvement, driven by 5S training and lean management, significantly optimizes workplace performance, with manufacturing seeing up to 50% productivity gains. Effective implementation involves comprehensive training, regular audits, digital documentation, and fostering a standardized work environment.

In today’s dynamic business landscape, optimizing the workplace is not just an advantage but a necessity for organizations aiming to stay competitive. The ever-changing market demands efficient operations, leading to increased productivity and reduced costs. Herein lies the challenge: disorganized workspaces often hinder progress and foster inefficiency. This article delves into a powerful solution—5S training and lean management principles—as a transformative workplace optimization technique. By implementing 5S continuous improvement methodologies and process standardization, organizations can cultivate an environment that fosters innovation, enhances productivity, and promotes a culture of excellence.

- Understanding the Foundation: 5S Training for Workplace Organization

- Implementing Lean Management: Streamlining Processes for Continuous Improvement

- The Art of Standardization: Process Normalization Techniques

- Cultivating a Culture: Sustaining 5S Continuous Improvement

Understanding the Foundation: 5S Training for Workplace Organization

The foundation of any successful workplace optimization strategy lies in effective organization and efficient processes. Among various techniques, 5S training has emerged as a powerful tool for achieving remarkable transformations in workplace environment and productivity. Rooted in lean management principles, 5S is a systematic approach that emphasizes order, cleanliness, and standardization. This method involves identifying and categorizing items within a workspace, discarding unnecessary elements, organizing tools and materials for easy accessibility, and continually maintaining the system through a culture of continuous improvement.

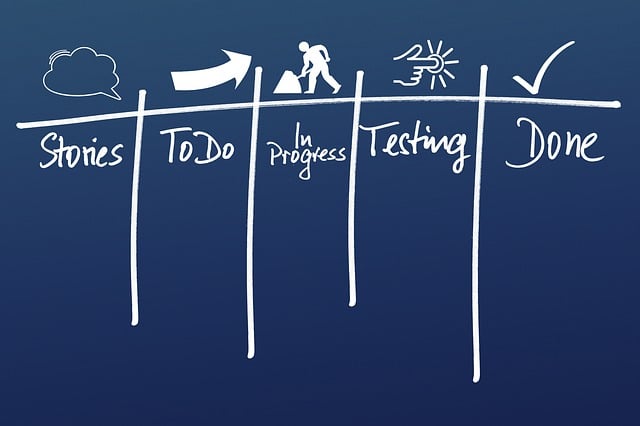

A structured 5S implementation typically includes five key steps: Sort, Set in Order, Shine (Clean), Standardize, and Sustain. For instance, a manufacturing facility might begin by sorting production lines to eliminate redundant equipment and processes. Then, they set items like tools and raw materials in specific, labeled locations for quick retrieval. Regular cleaning sessions, or ‘shining’, ensure an organized, safe environment that enhances worker efficiency. Process standardization naturally follows, streamlining operations and reducing waste. Finally, sustained 5S practices are fostered through ongoing training and regular audits to maintain the optimized workspace.

Studies have shown that organizations adopting 5S training can achieve significant improvements in productivity, quality, and employee satisfaction. A Japanese auto manufacturer, after implementing 5S, reported a 20% increase in production efficiency and a notable reduction in defects. These outcomes underscore the value of 5S as a foundational strategy for workplace optimization. To harness its full potential, organizations should prioritize comprehensive training, involving all employees to ensure buy-in and commitment to the continuous improvement process that 5S inherently promotes.

Implementing Lean Management: Streamlining Processes for Continuous Improvement

Lean Management, a powerful approach to workplace optimization, revolves around streamlining processes to achieve continuous improvement. At its core, this methodology emphasizes the efficient use of resources and the elimination of waste, fostering an environment where every task contributes to enhanced productivity and quality. One of the foundational practices within Lean is the 5S system, a structured framework designed to promote workplace organization and employee involvement. This involves sorting, setting in order, shining (cleaning), standardizing, and sustaining—a systematic approach that naturally lends itself to process standardization across various industries.

For instance, consider a manufacturing plant implementing 5S training. By ‘sorting’, employees identify and categorize tools and materials, eliminating clutter and enhancing accessibility. ‘Setting in order’ involves organizing these items based on frequency of use and workflow, ensuring each step is optimized. ‘Shining’ incorporates regular cleaning and maintenance routines, reducing downtime from equipment failures. Standardization through ‘standardizing’ processes ensures consistency in operations, enabling quicker resolution of issues and promoting a culture of continuous learning. Finally, ‘sustaining’ focuses on maintaining the established 5S practices over time, with regular audits and team engagement to ensure sustained improvements.

The benefits of this approach are supported by data from companies like Toyota, which attributes its remarkable efficiency gains to Lean principles. By systematically analyzing and improving processes, organizations can achieve significant reductions in waste, lead times, and defects. Moreover, employee engagement in the 5S continuous improvement process fosters a sense of ownership and pride, leading to higher morale and productivity. For businesses aiming to optimize their operations, integrating Lean Management and 5S training represents a proven strategy for driving sustainable success.

The Art of Standardization: Process Normalization Techniques

Standardization is a cornerstone of workplace optimization, enabling organizations to achieve efficiency, consistency, and excellence. At its core, this involves implementing structured processes that minimize variation and waste. Techniques such as 5S training and lean management are powerful tools for achieving process standardization naturally. The 5S methodology—Sort, Set in Order, Shine, Standardize, Sustain—provides a framework for organizing the workplace, streamlining operations, and fostering a culture of continuous improvement. For instance, a manufacturing facility can use 5S to create a visually organized workspace, ensuring that each employee follows standardized procedures for equipment maintenance, thereby reducing downtime and enhancing productivity.

Data from leading lean management practitioners reveals significant benefits associated with process standardization. Studies show that standardized processes can reduce error rates by up to 30%, increase throughput by 15%, and lower operational costs by as much as 20%. These improvements are not merely theoretical; they translate into tangible gains for businesses, including improved product quality, faster delivery times, and enhanced customer satisfaction. For example, a healthcare organization implementing lean principles and 5S training found that standardized admission procedures led to a 12% reduction in patient wait times and a 25% decrease in administrative errors.

To effectively embed process standardization into your workplace, organizations should invest in comprehensive 5S training for all employees. This involves teaching them not just the technical aspects of sorting and standardizing but also fostering a mindset focused on continuous improvement. Regular audits and performance reviews are crucial to maintaining standardized processes over time. Additionally, leveraging digital tools for documentation and tracking can help ensure that standards are consistently applied across different departments and locations. By integrating these practices into your operational DNA, you’ll create an environment where process efficiency becomes second nature, driving ongoing optimization and competitive advantage in today’s dynamic business landscape.

Cultivating a Culture: Sustaining 5S Continuous Improvement

Cultivating a culture of continuous improvement is a cornerstone of successful workplace optimization, particularly when leveraging techniques like 5S training and lean management principles. Organizations that embrace this philosophy strive for unparalleled efficiency, productivity, and employee engagement. The 5S methodology—Sort, Set in Order, Shine (Clean), Standardize, Sustain—serves as a powerful framework for achieving these goals. By implementing 5S training, businesses not only enhance workplace organization but also foster an environment where process standardization becomes second nature to employees.

For instance, a manufacturing facility can utilize 5S principles to transform its floor layout and operations. “Sort” involves removing clutter and keeping only essential tools and materials, streamlining workflow. “Set in Order” ensures everything is arranged logically, minimizing movement and saving time. Regular “Shine” sessions, or thorough cleaning, maintain hygiene and prevent accidents. Standardization, achieved through consistent application of 5S practices, leads to predictable outcomes and reduces errors. Finally, “Sustain” emphasizes the ongoing commitment to these improvements, ensuring the culture of efficiency persists over time.

Data supports the impact of such initiatives. A study by McKinsey found that companies adopting lean management practices experienced significant gains in productivity, with some seeing up to 50% improvement in certain areas. Moreover, employee satisfaction often rises as workers feel valued and empowered when contributing to continuous improvement efforts. To instill this culture effectively, leaders must model the behavior they wish to see, provide regular 5S training, and create a safe environment where employees feel comfortable suggesting enhancements. Regular audits and team discussions reinforce the importance of these practices, ensuring their longevity and adaptability to evolving business needs.