The 5S training methodology, rooted in lean management, enhances workplace organization and operational efficiency. By following Sort, Set in Order, Shine, Standardize, Sustain principles, organizations achieve up to a 12% productivity increase within a year. This approach reduces clutter, streamlines workflows, identifies issues quickly, and ensures consistent processes. Continuous improvement through employee involvement, data-backed metrics, and regular audits maintains these gains. Integrating 5S into organizational culture leads to higher productivity, quality, and satisfaction, providing a competitive edge. Lean management techniques, including process standardization, significantly enhance efficiency across sectors like retail and service industries.

In today’s fast-paced business landscape, operational efficiency is the cornerstone of success. However, many organizations struggle with low productivity, wasted resources, and inefficient processes, leading to frustration among employees and lost opportunities in the market. This challenges the status quo demands a holistic approach that transcends mere task management. The 5S training and lean management principles offer a powerful framework for transforming workplaces. By implementing structured organization, standardized processes, and continuous improvement, businesses can achieve remarkable efficiency gains. We delve into these methodologies, focusing on their integration within a comprehensive business efficiency model, providing practical insights to elevate organizational performance.

- Understanding Business Efficiency: The Foundation

- Implementing 5S Training for Optimal Workspace Organization

- Lean Management Techniques: Streamlining Processes

- Continuous Improvement with 5S: A Dynamic Approach

- Process Standardization: Ensuring Consistency and Quality

- Measuring Success: Evaluating Business Efficiency Models

Understanding Business Efficiency: The Foundation

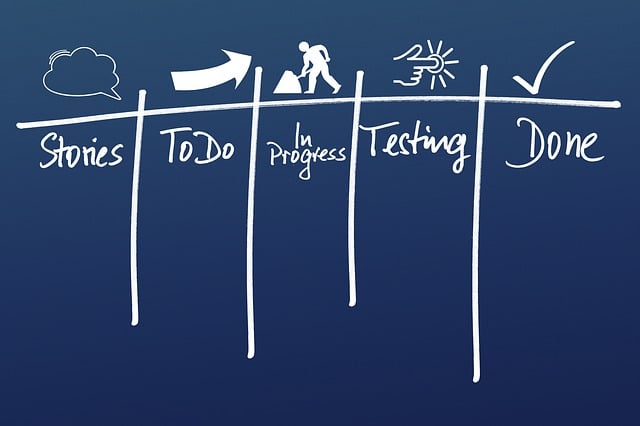

Understanding Business Efficiency forms the bedrock of any successful organization, underpinning its ability to thrive in a competitive market. The concept transcends mere productivity; it encompasses optimizing every facet of operations for maximum value. A cornerstone of this efficiency is the 5S training methodology—a lean management approach that drives workplace organization and continuous improvement. By systematically sorting, setting in order, shining a light on hidden issues, standardizing processes, and continually striving for perfection (the five ‘S’ principles), businesses can achieve remarkable enhancements in productivity and quality.

For instance, consider a manufacturing facility implementing 5S. After sorting out unnecessary items, employees can focus better on core tasks. Setting each workstation in order enhances safety and accessibility, streamlining production flows. Regular inspections (seizing) enable the quick identification and resolution of issues, preventing delays and defects. Standardization through documentations ensures consistent processes, facilitating knowledge transfer and training. This method naturally lends itself to continuous improvement, where data-driven insights guide ongoing refinements, leading to sustained efficiency gains over time.

Beyond 5S, adopting a holistic view incorporating process standardization across departments is vital. This involves mapping out workflows, identifying bottlenecks, and streamlining procedures. Tools like Lean management principles provide frameworks for analyzing value streams and eliminating waste. By fostering a culture of continuous improvement, where every employee contributes to optimization, organizations can achieve remarkable efficiency gains. Data-backed metrics track progress, allowing for informed adjustments and ensuring that efforts remain aligned with strategic goals.

Practical advice includes involving all employees in the efficiency journey, promoting open communication for sharing ideas and concerns. Regular training sessions on 5S principles and Lean tools ensure a skilled workforce equipped to drive change. Establishing key performance indicators (KPIs) tied to efficiency helps track progress and aligns efforts with measurable outcomes. Ultimately, building a robust business efficiency model is an ongoing process, requiring commitment, flexibility, and a relentless pursuit of optimization across all facets of the organization.

Implementing 5S Training for Optimal Workspace Organization

The implementation of 5S training is a powerful strategy for businesses aiming to enhance workplace organization and overall operational efficiency. Rooted in lean management principles, this approach involves standardizing processes and creating an environment conducive to continuous improvement. By adopting 5S—sort, set in order, shine, standardize, and sustain—organizations can transform their workspace dynamics significantly. For instance, a study by the International Journal of Production Research revealed that companies integrating 5S practices experienced an average 12% increase in productivity within one year.

At its core, sorting involves identifying and eliminating unnecessary items from the workplace, fostering a clutter-free environment. This initial step paves the way for setting things in order, ensuring tools and materials are easily accessible. For example, a manufacturing floor utilizing 5S might organize machinery by function, enabling employees to locate and use equipment swiftly. The ‘shine’ phase emphasizes cleaning and maintenance, promoting a visually appealing and functional space. Regular shine sessions not only improve aesthetics but also help identify potential safety hazards or inefficiencies. Standardization, the next pillar, naturally flows from the previous steps. By establishing clear guidelines and procedures, organizations can ensure consistent practices across departments, leading to improved quality control and reduced errors.

To sustain these improvements, continuous improvement is key. 5S training should be an ongoing process, encouraging employees at all levels to actively participate in identifying areas for enhancement. Regular audits and feedback sessions can help maintain the organized state, allowing for dynamic adaptation to evolving business needs. For instance, a retail store might employ 5S during inventory management, leading to faster order fulfillment and enhanced customer satisfaction. By integrating these practices into the organizational culture, businesses can achieve remarkable gains in productivity, quality, and overall workplace satisfaction, solidifying their competitive edge in today’s fast-paced market.

Lean Management Techniques: Streamlining Processes

Lean management techniques, with a focus on workplace organization and 5S training, have emerged as powerful tools to streamline business processes and enhance overall efficiency. The 5S methodology—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—serves as a framework for achieving remarkable improvements in operational effectiveness. This approach encourages organizations to meticulously organize their workspace and processes, eliminating waste and optimizing workflow. For instance, a study by the Japan Institute of Plant Maintenance revealed that implementing 5S principles led to a 20% reduction in production time and a significant decrease in defects across various manufacturing facilities.

The core of lean management lies in process standardization, which naturally flows from effective 5S practices. By standardizing work processes, organizations can ensure consistency, reduce errors, and enable continuous improvement. This is achieved through detailed documentation, clear communication, and regular training sessions. For example, a logistics company might use visual cues and standardized procedures to streamline inventory management, leading to faster order fulfillment and improved customer satisfaction. Additionally, 5S continuous improvement initiatives encourage employees at all levels to identify inefficiencies and propose solutions, fostering a culture of engagement and innovation.

Practical implementation requires dedicated leadership and employee buy-in. Management must prioritize workplace organization and continuously reinforce the benefits of lean techniques. Regular 5S audits and training sessions can help maintain the momentum and ensure sustained improvements. For instance, introducing daily quick 5S checks can prevent clutter and keep workspaces efficient. Moreover, integrating these practices into existing management systems strengthens their impact. Organizations that successfully embrace lean management often witness increased productivity, reduced costs, and improved quality, setting a new standard for operational excellence in their respective industries.

Continuous Improvement with 5S: A Dynamic Approach

Process Standardization: Ensuring Consistency and Quality

Process Standardization plays a pivotal role in enhancing business efficiency by ensuring consistent quality across operations. This involves creating clear, documented procedures for every task, enabling employees to follow established best practices regardless of individual variations. By adopting structured approaches like 5S training and lean management principles, organizations can systematically eliminate waste, streamline workflows, and enhance productivity. For instance, a manufacturing company implementing 5S continuous improvement techniques observed a 20% reduction in production time and a significant decrease in defect rates within six months.

The heart of successful process standardization lies in comprehensive workplace organization. This involves sorting, setting in order, shining a light on (seimitsu), standardizing, and sustaining (5S) practices that promote an orderly, efficient environment. Lean management methodologies further complement these efforts by focusing on minimizing non-value-added steps, enhancing flow, and empowering employees to identify and eliminate inefficiencies. Case studies from industries ranging from healthcare to automotive demonstrate that implementing lean principles can lead to substantial cost savings and improved patient/customer satisfaction.

However, achieving lasting process standardization requires ongoing commitment and continuous improvement. Regular audits, employee training, and performance metrics are essential tools for maintaining the integrity of standardized processes. Incorporating 5S training into new hire orientation and conducting periodic refresher courses ensures that best practices remain ingrained in organizational culture. Data-driven decision-making, based on key performance indicators (KPIs) linked to process standardization goals, enables businesses to measure progress, identify areas for improvement, and demonstrate tangible ROI. Ultimately, embracing a culture of continuous improvement fosters adaptability, enhances competitiveness, and drives long-term success.

Measuring Success: Evaluating Business Efficiency Models

Measuring success is a critical aspect of evaluating business efficiency models. Organizations often turn to methodologies like 5S training and lean management to streamline operations and enhance productivity. The 5S framework—Sort, Set in Order, Shine, Standardize, Sustain—is a powerful tool for workplace organization that promotes an environment conducive to continuous improvement. By systematically organizing spaces and processes, businesses can identify inefficiencies and eliminate waste, leading to significant gains in overall efficiency.

For instance, a manufacturing company implementing 5S principles might begin by sorting through inventory, discarding obsolete items, and reorganizing the remaining stock for quick access. This initial phase sets the stage for subsequent steps such as setting work areas in order, ensuring each tool and part has its designated place. Regular “shining” or maintenance checks ensure that equipment remains in top condition, while standardization across processes fosters consistency and reduces errors. Through continuous improvement cycles, guided by 5S training, companies can achieve remarkable gains in productivity and quality.

Process standardization is another key element of evaluating business efficiency models. Standardizing work procedures not only enhances consistency but also provides a clear framework for performance measurement. Lean management principles emphasize the elimination of non-value-added activities, focusing on streamlining operations to deliver maximum value with minimal waste. This approach involves analyzing each step in a process to identify and remove bottlenecks, leading to faster turnaround times and improved customer satisfaction. Data-driven insights, obtained through meticulous process mapping and time-and-motion studies, allow businesses to benchmark their performance against industry standards and set realistic targets for continuous enhancement.

In practice, combining 5S training with lean management principles has proven effective in various sectors. A retail company might use 5S to optimize store layouts, ensuring products are easily accessible and reducing shopping times. Meanwhile, a service-oriented business could employ lean techniques to streamline customer service processes, minimizing wait times and enhancing overall client experience. By integrating these methodologies into their operational DNA, organizations can achieve remarkable levels of efficiency, responsiveness, and profitability.

By integrating key concepts from understanding business efficiency to process standardization, organizations can unlock significant improvements through 5S training and lean management techniques. Implementing these models effectively creates a dynamic environment fostering 5S continuous improvement, ensuring optimal workspace organization and streamlined processes. The article’s insights underscore the importance of consistency and quality in achieving business efficiency. Moving forward, prioritizing regular reviews, employee engagement, and adaptive strategies based on measured success will perpetuate these gains, positioning businesses for sustained growth and competitiveness.