Kaizen, a Japanese philosophy emphasizing continuous improvement, drives efficiency gains through incremental changes. 5S training, a core component, creates organized workplaces using five steps: Sort, Set in Order, Shine (Clean), Standardize, and Sustain. This structured approach enhances productivity, reduces waste, and improves quality across industries by streamlining processes, fostering innovation, and empowering employees to identify inefficiencies. Successful implementation requires leadership commitment, employee engagement, regular audits, and continuous refinement for sustained improvements.

In today’s competitive business landscape, the ability to streamline operations and enhance productivity is paramount. Kaizen, a Japanese concept emphasizing continuous improvement, offers a powerful framework for achieving these goals. The traditional 5S training methodology—a cornerstone of lean management—serves as a practical tool within this approach, focusing on workplace organization and process standardization. This article delves into the intricacies of Kaizen-based organizational methods, providing valuable insights for experts seeking to enhance their expertise in continuous improvement strategies. By exploring 5S principles and their application, we aim to equip professionals with the tools to drive efficient and effective change within any organization.

- Understanding Kaizen and Its Principles

- Implementing 5S Training for Workplace Organization

- Lean Management: Process Standardization Techniques

- Continuous Improvement Through 5S Methodology

Understanding Kaizen and Its Principles

Kaizen, a Japanese term meaning “continuous improvement,” forms the core philosophy of a Kaizen-based organizational method. This approach emphasizes incremental, systematic changes to enhance efficiency and productivity in various business processes. Unlike traditional management strategies that focus on drastic overhauls, Kaizen encourages small, continuous adjustments that collectively lead to significant improvements over time. The concept has its roots in lean management principles, specifically the 5S training framework—Sort, Set in Order, Shine (Clean), Standardize, and Sustain—which aims to create a clean, organized, and standardized workplace environment.

The effectiveness of Kaizen lies in its ability to integrate continuous improvement into the day-to-day operations of an organization. By fostering a culture of incremental change, workers at all levels become active participants in identifying inefficiencies and implementing solutions. For instance, a manufacturing plant utilizing Kaizen principles might involve employees in regular 5S audits, where they identify waste, streamline processes, and implement simple fixes to enhance productivity. This hands-on involvement not only empowers employees but also ensures that improvements are tailored to the specific needs and workflows of the organization.

Implementing Kaizen requires a commitment to process standardization and a deep understanding of workplace dynamics. It involves breaking down complex tasks into simpler steps, making them more manageable and easier to optimize. For example, a retail store could standardize its inventory management process by introducing digital tracking systems, simplifying order placement, and establishing clear responsibilities for stock maintenance. This not only reduces errors but also enables faster response times to customer demands. The success of Kaizen lies in its adaptability; what works in a manufacturing setting may differ from a service industry, making it crucial to tailor the approach to suit the unique requirements of each organization.

Implementing 5S Training for Workplace Organization

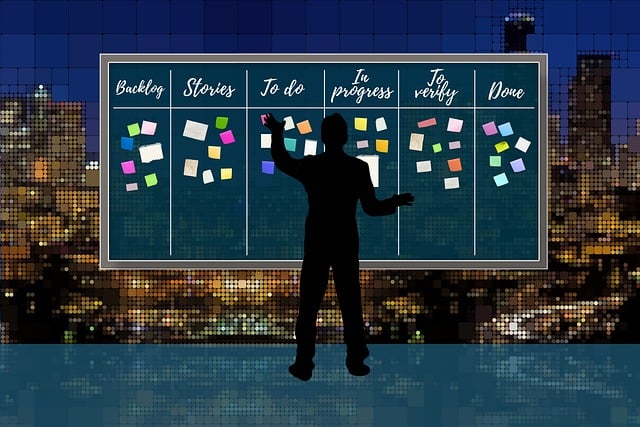

The implementation of 5S training is a powerful strategy within the lean management framework to transform workplace organization and foster continuous improvement. Originating from Japan, the 5S methodology—Sort, Set in Order, Shine, Standardize, and Sustain—has become a global standard for process standardization and quality control. This approach not only enhances productivity but also creates an environment conducive to innovation and employee engagement. By systematically organizing work areas, teams can identify inefficiencies and streamline operations, ultimately driving organizational success.

At the core of 5S training lies the sorting process, where every item within a workplace is meticulously evaluated for its purpose and value. This step involves decluttering and discarding unnecessary items, ensuring only essential tools and resources remain. For instance, a manufacturing facility might sort through its inventory, keeping only the most frequently used parts readily accessible, reducing waste, and minimizing downtime due to part search times. Following sorting, the ‘set in order’ phase involves arranging items logically, often utilizing storage systems and labeling for easy retrieval. This systematic organization allows employees to locate tools and materials quickly, improving workflow efficiency.

Moreover, 5S training emphasizes the importance of maintaining a clean and organized workplace. The ‘shine’ aspect encourages regular cleaning routines, ensuring that equipment is free from debris or defects that could hinder performance. Regular shining sessions not only maintain the aesthetic appeal of the workspace but also prevent potential safety hazards. Standardization, the fourth pillar, involves creating standardized procedures for each task, training employees to perform them consistently. This ensures process efficiency and facilitates knowledge sharing among team members. For example, a healthcare facility might standardize patient intake processes, ensuring every patient receives consistent care regardless of which staff member assists them.

To ensure sustainability, 5S training programs incorporate continuous improvement practices. Regular audits and feedback sessions are conducted to identify areas for further optimization. By engaging employees at all levels in the 5S process, organizations can foster a culture of ownership and accountability. This collaborative approach leverages the expertise of front-line workers, leading to more effective solutions tailored to their unique challenges. Data from successful implementations suggest that companies adopting 5S training can experience significant improvements in productivity, reduced waste, and enhanced employee satisfaction, ultimately contributing to their competitive advantage in the market.

Lean Management: Process Standardization Techniques

Lean management, rooted in the principles of continuous improvement and process optimization, is a powerful approach for enhancing workplace organization and efficiency. At its core, lean management emphasizes the elimination of waste, streamlining processes, and fostering a culture of standardizing work practices. One of the key techniques within this framework is 5S training, a system that goes beyond simple workplace organization to create an environment conducive to continuous improvement.

The 5S method—Sort, Set in Order, Shine (or Clean), Standardize, and Sustain—is a structured approach to process standardization. It begins with sorting, where unnecessary items are removed, followed by setting work areas in order for easy access and efficiency. The ‘shine’ step involves cleaning and maintaining the workspace, ensuring it remains organized. Standardization is achieved through consistent application of best practices and documentation, often facilitated by visual management tools. Finally, sustaining these standards requires ongoing training and engagement from all levels of the organization.

For instance, a manufacturing company implementing 5S might begin by sorting their inventory, keeping only essential items on site. They would then set up workstations in a logical flow, ensuring operators have everything they need within arm’s reach. Regular cleaning and maintenance schedules are established to prevent clutter from reappearing. Standard operating procedures are documented and visually displayed, guiding employees through each step of the production process. Through such structured improvements, organizations can achieve remarkable results, including increased productivity, reduced waste, and improved quality.

To integrate lean management effectively, companies should invest in comprehensive 5S training for all staff. This involves teaching the principles, providing practical exercises, and encouraging continuous improvement at every level of the organization. Regular audits and performance reviews can help maintain standards while identifying further opportunities for refinement. By embracing these techniques, organizations can create a culture of efficiency and excellence that drives success in today’s competitive market.

Continuous Improvement Through 5S Methodology

Kaizen, the Japanese concept of continuous improvement, has revolutionized organizational methods worldwide. At the heart of this philosophy lies the 5S methodology, a powerful tool for driving workplace organization and fostering a culture of persistent enhancement. This approach, deeply rooted in lean management principles, not only streamlines processes but also empowers employees to take an active role in their work environment’s optimization.

The 5S framework comprises five pillars: Sort, Set in Order, Shine (Clean), Standardize, and Sustain. Through rigorous 5S training, organizations can achieve remarkable results. For instance, a manufacturing facility implementing 5S found a 20% increase in production efficiency within six months, primarily attributed to improved workflow visibility and reduced waste. This success is not isolated; similar studies have demonstrated consistent gains in productivity, quality, and employee satisfaction following the adoption of 5S continuous improvement practices.

Effective 5S implementation requires commitment from leadership and active participation from all levels of staff. Training programs should focus on teaching employees not only the technical aspects of sorting and organizing but also the importance of maintaining a disciplined approach. Regular audits and ongoing refinement are key to sustaining the momentum generated by initial 5S initiatives. By embracing a mindset that views every task as an opportunity for enhancement, organizations can naturally evolve towards process standardization, ensuring sustained competitive advantage in today’s dynamic market.

By integrating Kaizen-based organization methods, including 5S training and lean management techniques, businesses can significantly enhance workplace organization and foster a culture of continuous improvement. The article’s key insights highlight the power of process standardization, demonstrating that even small changes can lead to substantial efficiency gains. Implementing 5S methodologies not only streamlines operations but also empowers employees to actively participate in identifying and eliminating waste. Lean management principles, when coupled with regular 5S training, create a robust framework for optimizing processes, reducing costs, and improving overall productivity. Moving forward, organizations should prioritize these strategies as practical next steps, ensuring they cultivate a mindset of continuous enhancement that drives success in today’s competitive market.