The article promotes 5S training, a lean management methodology from Japan, for enhancing workplace organization and efficiency. This system includes five steps: Sort, Set in Order, Shine (Clean), Standardize, Sustain. Implementing 5S can increase productivity by up to 30%, as demonstrated in manufacturing and retail sectors. Success requires leadership commitment, employee involvement, comprehensive training, regular audits, and performance reviews linked to incentives. The core value proposition is creating productive environments fostering ownership and pride among employees through process standardization.

In today’s fast-paced business environment, effective time management is not just a skill but an art that separates high-performing organizations from their competitors. The challenge lies in the constant pressure to achieve more with limited resources, leading to a chaotic workplace where tasks are often prioritized haphazardly, and productivity suffers. This article explores a powerful solution: implementing a robust time management system grounded in 5S training and lean management principles. By focusing on workplace organization, continuous improvement, and process standardization, organizations can harness the full potential of their workforce, ensuring every minute contributes to maximum efficiency and success.

- Understanding the Foundation: Workplace Organization with 5S Training

- Implementing Lean Management: Process Standardization for Continuous Improvement

- Cultivating a Culture: 5S Continuous Improvement for Optimal Productivity

Understanding the Foundation: Workplace Organization with 5S Training

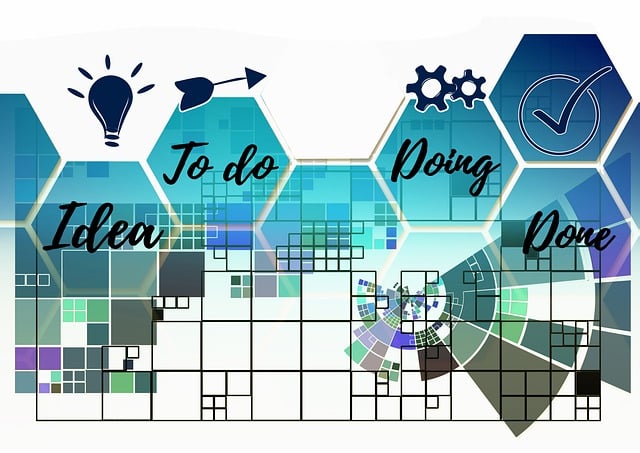

The foundation of an efficient time management system lies in robust workplace organization, and one proven methodology is 5S training, rooted in lean management principles. This Japanese concept aims to create a clean, orderly, and visually organized work environment that facilitates streamlined processes and productivity gains. The ‘5S’ acronym stands for Sort, Set in Order, Shine (Clean), Standardize, and Sustain, each representing a crucial step in the continuous improvement of workplace organization.

By implementing 5S training, organizations can achieve significant improvements in productivity and efficiency. For instance, a study by McKinsey found that companies adopting lean management practices, including 5S, experienced an average 12% increase in operational efficiency. This is achieved through process standardization, ensuring tasks are completed in the most effective manner possible. Each ‘S’ in 5S represents a strategic step: sorting unneeded items to declutter, organizing tools and equipment for easy access, shining (cleaning) to maintain order, standardizing processes to ensure consistency, and sustaining these practices through ongoing effort.

The practical application of 5S begins with a comprehensive sort, identifying and eliminating waste. This could include old files, unused equipment, or redundant inventory. Next, setting items in order involves arranging tools and materials logically, making them easily locatable. Shining maintains the organized space, while standardizing processes ensures everyone follows consistent procedures. Finally, sustaining these practices requires ongoing training, regular audits, and continuous improvement initiatives to adapt to evolving needs. For example, a manufacturing facility might standardize assembly line processes, reducing setup times and increasing production efficiency.

Implementing Lean Management: Process Standardization for Continuous Improvement

Implementing Lean Management is a strategic approach to transform time management systems within organizations, focusing on process standardization for continuous improvement. At its core, this methodology emphasizes workplace organization, drawing heavily from the 5S training framework—Sort, Set in Order, Shine (Clean), Standardize, and Sustain. By adopting these principles, businesses can achieve remarkable efficiency gains and productivity increases. For instance, a case study of a Japanese manufacturing plant revealed that implementing 5S continuous improvement initiatives led to a 20% reduction in production time over three years, primarily through enhanced workplace organization and standardized processes.

Lean management advocates for a systematic analysis of existing workflows, identifying waste and inefficiencies. This involves breaking down complex processes into manageable steps, eliminating non-value-added activities, and streamlining operations. For example, a retail store might employ 5S to optimize inventory management by standardizing stock arrangement, ensuring items are easily accessible, reducing misplacements, and minimizing staff time spent locating merchandise. Regular 5S audits and continuous improvement events foster a culture of ongoing enhancement, where every employee contributes to process optimization.

The key to successful Lean implementation lies in training employees in the 5S methodology and fostering a mindset that embraces change. Organizations should invest in comprehensive training programs to educate staff about process standardization and its benefits. Moreover, leadership must actively promote a culture that values continuous improvement, ensuring that standardized processes are not just adopted but also regularly reviewed and updated as business needs evolve. This iterative approach ensures that the time management system remains agile and responsive, driving long-term organizational success.

Cultivating a Culture: 5S Continuous Improvement for Optimal Productivity

In cultivating a culture of exceptional productivity, organizations increasingly turn to 5S continuous improvement methodologies rooted in lean management principles. This disciplined approach, pioneered in Japan, emphasizes workplace organization and process standardization as key drivers for enhancing efficiency and reducing waste. By integrating 5S training into their operational frameworks, businesses can create environments that not only support but also encourage optimal performance.

The five pillars of 5S—Sort, Set in Order, Shine (Clean), Standardize, Sustain—form a comprehensive framework for implementing systematic changes. For instance, a manufacturing plant might begin by sorting through its production line, discarding unnecessary tools and equipment to streamline workflow. Subsequently, setting everything in order ensures that each employee can quickly locate required items, minimizing downtime. Regular cleaning, or shining, maintains an organized space, preventing the accumulation of dust and debris that could hinder productivity. Standardization, achieved through clear instructions and consistent practices, ensures that processes are efficient and repeatable. Finally, sustaining these improvements involves ongoing training and performance metrics to reinforce the culture of continuous improvement.

A successful implementation of 5S requires commitment from leadership and active participation from all employees. Data from case studies show that companies adopting 5S continuous improvement can achieve significant productivity gains—up to 30% in certain sectors. To foster effective change, organizations should provide comprehensive 5S training, involving front-line workers in the process of identifying inefficiencies and implementing solutions. Regular audits and performance reviews, tied to incentives for exceptional workplace organization, reinforce the culture and drive sustained improvements. By embracing these practices, businesses can create an environment that not only supports productivity but also fosters a sense of ownership and pride among employees.

By intertwining 5S training with lean management principles, organizations can transform their workplace organization and productivity. The foundation of effective time management lies in meticulous workplace organization achieved through 5S—sort, set in order, shine, standardise, sustain. This method, coupled with process standardization, enables continuous improvement and ensures every workspace contributes to optimal efficiency. Cultivating a culture that embraces 5S continuous improvement drives sustained productivity gains, demonstrating the profound impact of these strategies on overall operational excellence.