In Livermore, California, Six Sigma has been instrumental in elevating business efficiency and product quality through its rigorous methodology. The Six Sigma certification process, particularly the Black Belt level, is a testament to an individual's mastery of process improvement techniques that blend Lean principles with data-driven strategies. This comprehensive approach, encapsulated in the DMAIC framework, enables professionals to systematically analyze, improve, and control processes to meet or exceed customer expectations while optimizing efficiency. Local businesses have seen significant enhancements by integrating lean Six Sigma principles into their design and production processes, which has positioned Livermore as a leading example of Six Sigma excellence. Advanced Six Sigma training programs in the area offer education on both foundational six sigma concepts and the intricate aspects of lean Six Sigma, ensuring that participants are well-equipped to lead continuous improvement initiatives and maintain high standards of quality control. The pursuit of Six Sigma black belt status represents a commitment to professional growth and is essential for those aiming to advance their careers within Livermore's manufacturing sector. Six Sigma training in Livermore not only covers the methodology but also focuses on applying lean Six Sigma principles for waste elimination and resource optimization, making it a cornerstone for businesses looking to sustain growth and innovation.

In Livermore, California, the integration of Six Sigma into product and process design is not just a quality standard; it’s a transformative approach that has reshaped manufacturing excellence. This article delves into the design for six sigma (DFSS) approach, which leverages lean Six Sigma principles to create robust products and processes. We explore the significance of Six Sigma certification as a stepping stone to expertise in Livermore’s burgeoning manufacturing sector, providing insights into what Six Sigma is and its profound impact on innovation. A spotlight is cast on the critical role of Six Sigma Black Belts, who are instrumental in steering design and process outcomes toward unparalleled efficiency and quality. Furthermore, we examine the benefits of advanced Six Sigma training for those looking to elevate their skills and contribute to Livermore’s legacy of manufacturing prowess. Join us as we navigate the Six Sigma methodology, ensuring that your next project not only meets but exceeds the standards of excellence in this dynamic industry.

- Mastering Lean Six Sigma Principles for Optimal Product and Process Design in Livermore, CA

- Six Sigma Certification: A Pathway to Expertise in Livermore's Manufacturing Excellence

- Understanding Six Sigma: A Comprehensive Guide to the Methodology for Livermore Innovators

- The Role of Six Sigma Black Belts in Transforming Design and Process Outcomes in Livermore

- Elevating Design for Six Sigma (DFSS) with Advanced Training in Livermore, CA

Mastering Lean Six Sigma Principles for Optimal Product and Process Design in Livermore, CA

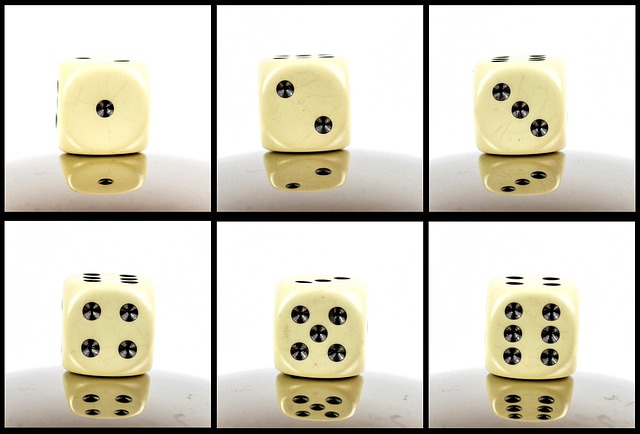

In Livermore, California, businesses are leveraging Lean Six Sigma principles to design products and processes that epitomize efficiency and quality. The Six Sigma methodology, a data-driven approach to process improvement, has become a cornerstone for organizations aiming to achieve near-perfection in their operations. By integrating Lean techniques that focus on eliminating waste and optimizing resource utilization, companies in Livermore can significantly enhance their product design and production processes. Six Sigma certification is a testament to an individual’s proficiency in these techniques, with the Black Belt certification being a particularly esteemed credential that signifies advanced expertise. This certification, through its rigorous training, equips professionals with the tools necessary to analyze, improve, and control their processes. For those looking to embark on a Six Sigma journey, training programs are available to master the Lean Six Sigma principles, which encompass a holistic approach to problem-solving that is both systematic and data-centric. By adopting these principles, businesses in Livermore can design products that not only meet but exceed customer expectations while simultaneously streamlining processes for greater efficiency. This synergy between Lean and Six Sigma offers a powerful combination for continuous improvement, ensuring that products are designed with the highest quality standards from conception to deployment.

Six Sigma Certification: A Pathway to Expertise in Livermore's Manufacturing Excellence

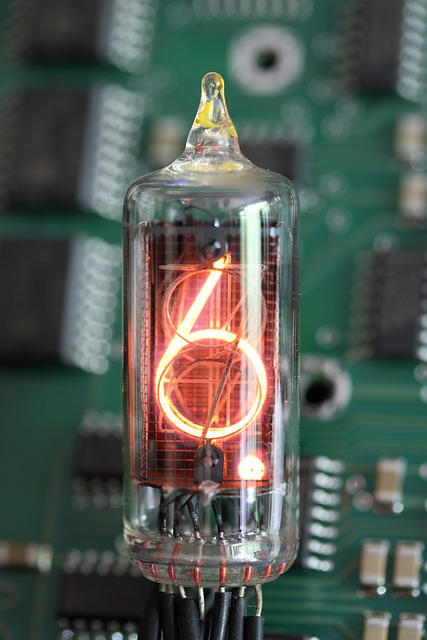

In Livermore, California, the integration of Six Sigma principles within the manufacturing sector has become a hallmark of excellence, driving productivity and quality to new heights. Six Sigma, a data-driven approach aimed at enhancing process efficiency by reducing variability and defects, has found a receptive environment in this thriving hub. For professionals seeking to deepen their expertise and contribute significantly to Livermore’s manufacturing prowess, Six Sigma certification stands out as a transformative credential. This certification not only validates one’s understanding of the Six Sigma methodology but also equips them with the tools necessary to implement lean Six Sigma principles effectively. The curriculum for Six Sigma training encompasses a comprehensive study of the Six Sigma black belt, DMAIC (Define, Measure, Analyze, Improve, Control) methodology, and other critical aspects of this rigorous framework. By achieving certification, individuals gain the competencies required to lead process improvement initiatives, ensuring that Livermore’s manufacturers can consistently produce high-quality products that meet or exceed customer expectations.

The journey towards becoming a Six Sigma black belt is challenging but rewarding, offering a structured pathway for continuous learning and application of lean Six Sigma principles. Aspiring candidates embark on this path with the aim of mastering statistical process control, design of experiments, and project management techniques that are integral to the Six Sigma approach. The certification not only signifies a level of expertise but also demonstrates a commitment to ongoing professional development, which is crucial in the ever-evolving landscape of manufacturing excellence in Livermore. By adhering to the Six Sigma methodology, businesses in this region can achieve sustainable growth and maintain a competitive edge, all while fostering an environment where innovation and quality are the norms.

Understanding Six Sigma: A Comprehensive Guide to the Methodology for Livermore Innovators

Six Sigma is a rigorous statistical improvement methodology that aims to reduce defects and variability in manufacturing processes, products, or services by applying a set of principles and tools. This methodology, which originated at Motorola in the 1980s, has since become a global standard for quality control and process optimization. For Livermore innovators seeking to enhance their product design and streamline operations, understanding Six Sigma is not just beneficial—it’s imperative. The Six Sigma framework encompasses lean Six Sigma principles, which integrate the lean approach with the Six Sigma methodology, providing a comprehensive toolkit for eliminating waste and driving efficiency.

Leveraging Six Sigma certification, practitioners can become adept in employing its DMAIC (Define, Measure, Analyze, Improve, Control) structure to identify critical problems, develop solutions, and implement controls to sustain gains. Aspiring Six Sigma Black Belts in Livermore will find that this certification is a testament to their commitment to quality and process excellence. Through Six Sigma training, they gain the skills necessary to analyze data and make informed decisions, leading to products and processes that are not only reliable but also exceed customer expectations. By adopting lean Six Sigma principles, businesses in Livermore can achieve substantial improvements in their operations, ensuring that every aspect of the production process is fine-tuned for peak performance.

The Role of Six Sigma Black Belts in Transforming Design and Process Outcomes in Livermore

In Livermore, California, Six Sigma Black Belts play a pivotal role in harnessing the principles of Six Sigma to elevate design and process outcomes. These experts are the vanguard of innovation within organizations, leveraging their deep understanding of the Six Sigma methodology to refine products and processes. The Six Sigma Black Belt certification signifies mastery over the DMAIC (Define, Measure, Analyze, Improve, Control) framework, a core component of the Six Sigma approach. This certification is not merely a testament to their expertise but also to their ability to apply lean Six Sigma principles effectively. By doing so, they drive efficiency and quality, ensuring that the end products meet or exceed customer expectations. The Black Belts’ role extends beyond mere problem-solving; they are catalysts for a culture of continuous improvement. Their work in Livermore exemplifies the transformative power of Six Sigma training, where every stage of product design and process development is meticulously scrutinized to minimize variability and maximize performance. Through their application of Six Sigma tools and techniques, Black Belts contribute significantly to the reliability and success of new designs and processes, thereby positioning Livermore’s businesses at the forefront of innovation and quality excellence.

Elevating Design for Six Sigma (DFSS) with Advanced Training in Livermore, CA

In Livermore, California, the integration of Six Sigma into product and process design is not just a strategic advantage but a mandatory framework for excellence. Advanced training programs in the area are elevating Design for Six Sigma (DFSS) to new heights by incorporating the latest lean Six Sigma principles, ensuring that practitioners are well-versed in the six sigma methodology. These programs often culminate in coveted six sigma certification, which validates an individual’s proficiency and commitment to quality and process improvement. For those seeking to deepen their understanding of what is six sigma and its impact on business efficiency, these trainings are particularly beneficial. They cover a range of topics from the foundational aspects of six sigma to the nuances of lean Six Sigma principles, providing participants with a comprehensive toolkit that can be applied to real-world scenarios. The focus on Six Sigma black belt training in Livermore equips professionals with the skills necessary to lead complex projects, optimize processes, and drive continuous improvement within their organizations. By embracing this rigorous training, local businesses are empowered to design products and processes that meet the stringent standards set by Six Sigma, thereby enhancing their competitiveness and ensuring a high degree of customer satisfaction. This commitment to excellence through advanced Six Sigma training is setting a new standard for product development and process optimization in Livermore, CA, and beyond.